❤️🪚❤️ 14 % Valentine’s discount on orders over €100 with promo code VALENTOOL! View terms & conditions

DICTUM | More than tools - craftsmanship perfected

People. Tools. Knowledge.

For more than 170 years, we have been bringing them together in perfect harmony.

Those who create lasting value with their own hands will find tools and materials at DICTUM that inspire.

NexTool® Multitool »Mini Sailor«: For everyday use

- compact 9-in-1 multitool for everyday use, travel and outdoor activities

- combines needle-nose/standard pliers, wire cutter, mini scissors, pocket knife, SIM card pin and more

- handy size (only 80 g) makes the multitool especially easy to carry

FEATURED PRODUCTS

NEW ARRIVALS

JAPANESE SAW ADVISOR

As one of Europe’s leading suppliers of Japanese hand tools, we have decades of experience and set the highest standards for quality and performance. Need help choosing? Try our Japanese Saw Advisor – the smart tool that guides you to the perfect saw for your needs.

CUSTOMER FAVOURITES

DICTUM WORKSHOPS

Mastering a craft takes more than just skill – it takes knowledge, experience and the right tools. Our aim is to offer you the complete package. In our craft courses, internationally renowned instructors share their expertise with beginners and advanced hobbyists alike. Fully equipped course workshops provide the ideal setting for focused, creative work.

Our WORKSHOPS- ONLINE & ON SITE

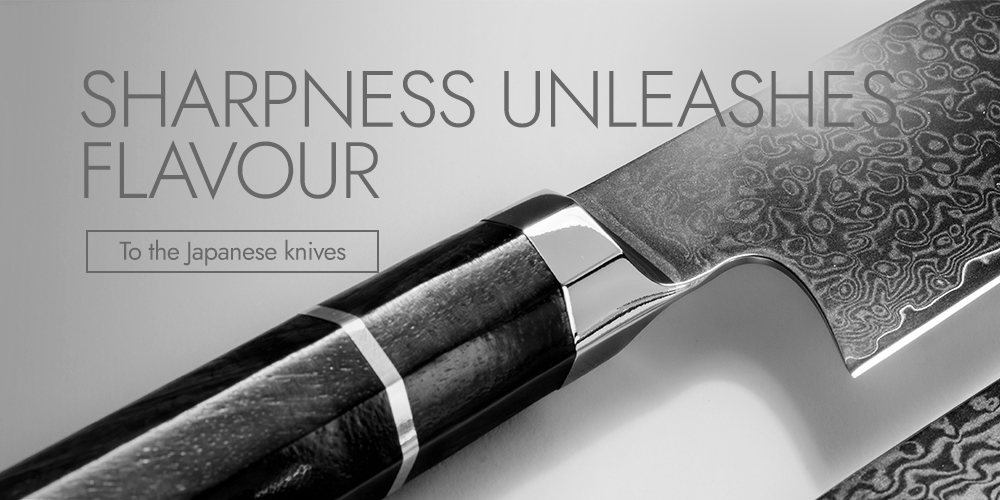

EXPERT KNOWLEDGE JAPANESE KNIVES

Nowhere else has the art of food preparation been refined to such a degree as in Japan. The most important tool in this culinary tradition is the hocho – the hand-forged Japanese kitchen knife. For centuries, small Japanese forges have produced outstanding blades in traditional forms, often handcrafted with exceptional skill. These knives are prized by professionals and enthusiasts alike for their superb ergonomics, razor-sharp edges and exceptional edge retention – ideal for precise, effortless cutting.

YOU MIGHT BE INTERESTED IN THE FOLLOWING BLOG TOPICS

Basic tool kit

Read blog post

Basic knowledge of timber joints

Read blog post

Vernier callipers explained

Read blog post