Saws

-

Woodworking / metalworking

-

Saws

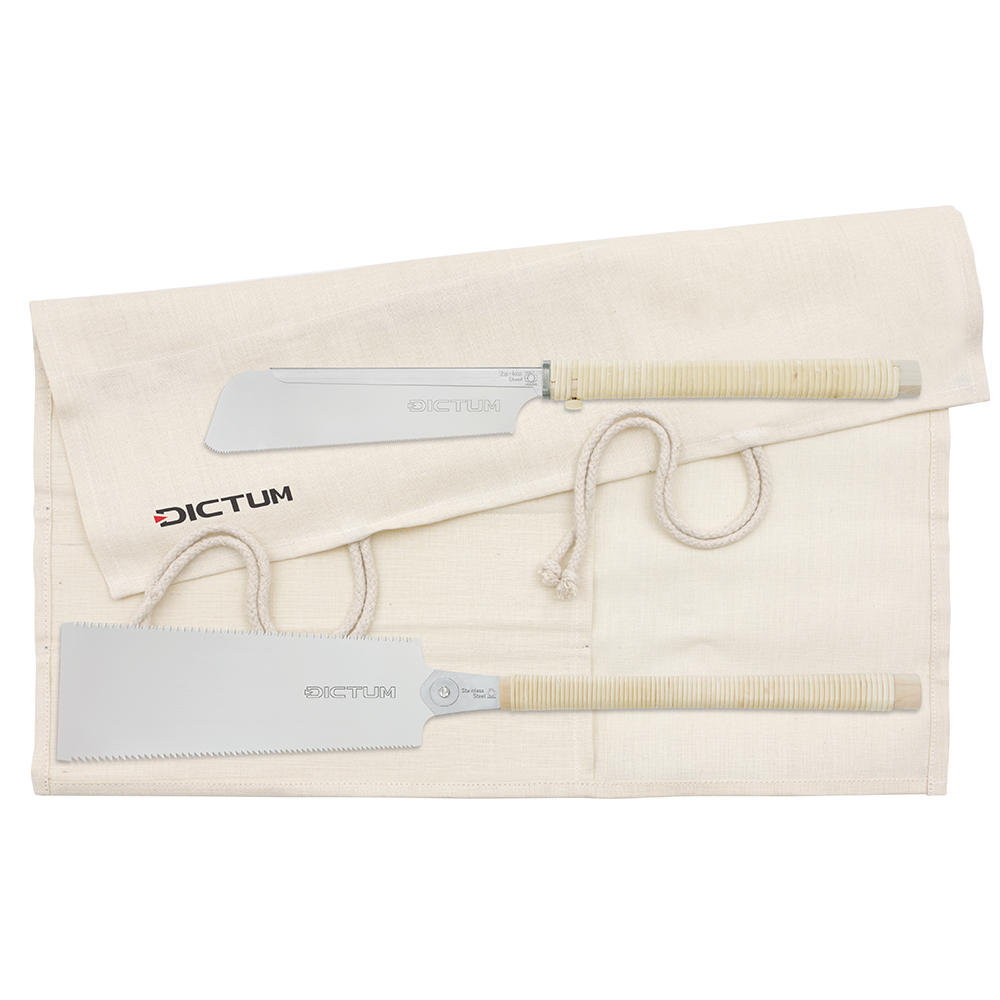

- Japanese saws with interchangeable blade

- Japanese saw sets

- Saw cases

- Classic handmade Japanese saws

- Japanese folding saws (woodworking)

- Western backsaws

- Bow saws

- Stair saws / groove-cutting saws

- Hand saws / jack saws

- Veneer and flush-cutting saws

- Coping saws

- Compass saws

- Saws for special materials

- Mitre saws

- Saw guides / mitre boxes

- Compact saws / mini saws

- Beam saws

- Saws for dovetails

- Model-making saws

- Outdoor saws

- Branch saws

- Saw-set pliers and sharpening devices for saws

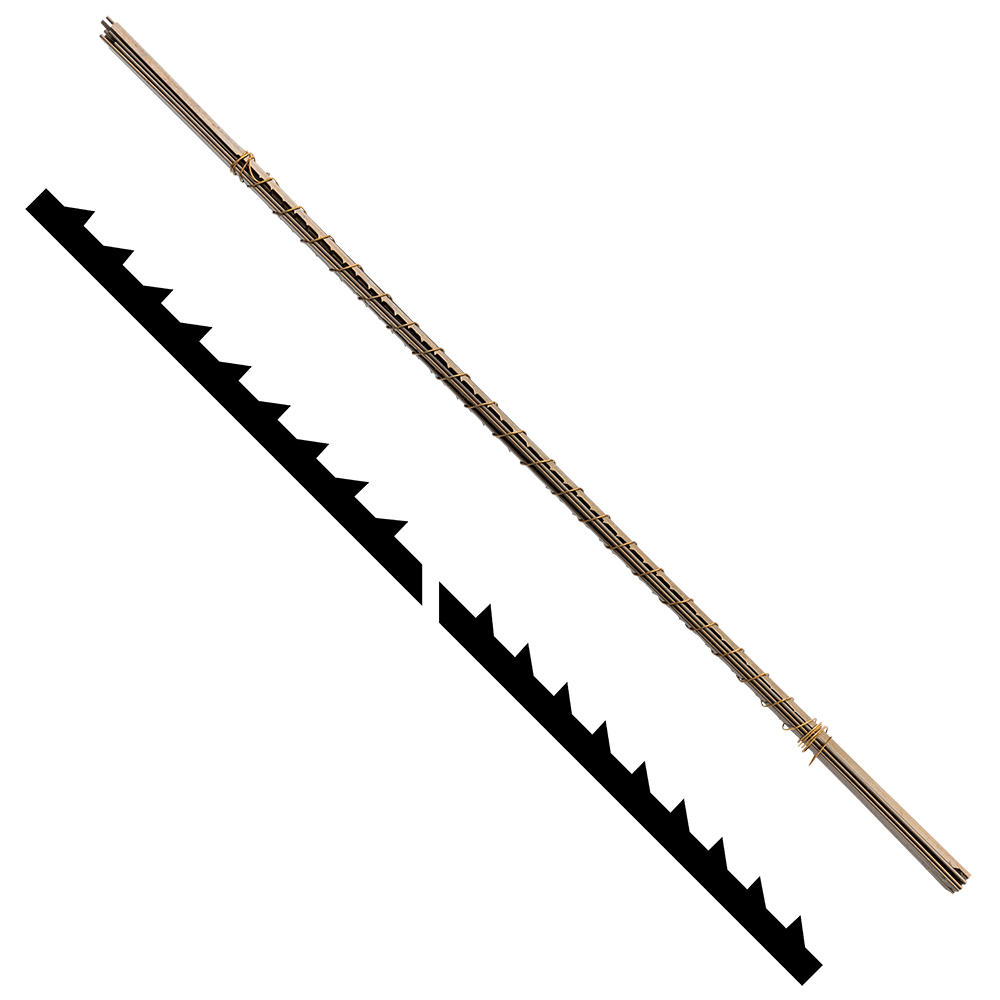

- Spare parts for saws

- Corded saws and cordless saws for wood

- Chisels

- Carving tools

- Axes and hatchets

- Hammers, nails & pry bars

- Planes

- Woodturning tools & lathes

- Rasps & files

- Measuring and inspection tools

- Scribing & cutting tools

- Routing & drilling tools

- Clamps

- Screwdriving tools

- Pliers

- Workshop equipment & tool sets

- Blacksmithing / blade finishing

- Engraving tools

-

Saws

- Leatherworking, papercraft & upholstery tools

- Stone working tools

- Tools for kids

Saws

SAWS EXPERTISE

Which handsaw to buy?

If you are interested in traditional woodworking by hand, the range of saws on offer is huge. You can choose between Western saws such as the Bow saws, frame saws, tine saws, fine saws and back saws as well as traditional Japanese saws such as Ryoba, Dozuki and Kataba. Or are you looking for a garden saw or pruning saw? Unfortunately, there is no universal saw that can do everything. Our tips for buying a handsaw:

- Firstly, decide what you want to use the saw for (precise or rough cuts, Material: metal, dry or fresh wood, plastic, required cutting depth, etc.). This will narrow down your choice of Saws.

- Which Saws do you know or have experience with? Positive or negative experiences can often be used to rule out or narrow down which points a Saws must fulfil for you. Make a note of these points and ask our specialist advisors.

- Your personal quality requirements. Do you need the Saws to repair something from time to time and to carry out small hobby tasks? Then an inexpensive handsaw is usually sufficient. In this case, you should opt for a model with an interchangeable blade system and universal toothing or double toothing. This allows you to work in different cutting directions and replace blunt blades easily and conveniently. Or would you like to delve deeper into woodworking and build more complex workpieces yourself in the long term? Then it makes sense to buy Saws for different Cutting directions and to get information and advice on power tools.

How do I find the right saw blade or saw?

The following criteria apply to circular saws, Compass saws, Bandsaws as well as to the saw blades of handsaws:

Cutting direction. There are different tooth shapes for circular saws, jigsaws and handsaws for longitudinal cuts and cuts across the grain. For cuts in the direction of the grain, the saw must cut the grain out of the composite, the tooth shape is similar to a plane iron. For cuts across the grain, the saw must cut through the grain; the teeth also have lateral cutting edges.

- Material. Different materials, such as solid wood or panel material, plastic or metal, require different tooth shapes and steel grades (e.g. WM, HSS) or differently hardened teeth.

- Material thickness. Tooth pitch or the distance between the saw teeth should be increased as the cutting depth increases. The so-called chip space is located between the teeth. This must be large enough to be able to transport the chips out during sawing. If it is too small, the saw blade will clog and the saw will lose performance or stop.

- Cutting quality. A saw blade for rough cuts has a coarser pitch than a fine-cut saw blade for precise sizing or making wood joints.

Always choose a saw blade that is suitable for the workpiece, task and material. The right saw blade makes cutting easier, improves the cutting result and also ensures greater safety. We offer suitable saw blades or saw blades recommended by the Manufacturer for all machines and hand saws.

Which Saws belong in the basic power tool kit?

Compass saws. A pendulum action jigsaw is part of the machine equipment in many households. It is very versatile, you can use it to saw mouldings, cut laminate flooring to size and even build a birdhouse. The jigsaw blades have a decisive influence on the quality of the cuts and should be matched to the Material and radius of the saw cut.

Portable circular saws, Circular bench saws and Chop saws. With a plunge-cut circular saw with guide rail, you can Saws almost everything that is otherwise cut on a circular bench saw. One advantage of the Plunge-cut saws is that they take up less space. When working with a Portable circular saws, you only need the space required for the cut. Circular bench saws also require space in front of and behind the saw table. A circular bench saw is worthwhile when cutting more complex pieces of furniture with many parts in different dimensions. Precise adjustment and exact repetitions are much faster with a circular bench saw. Small parts and narrow mouldings can also be cut faster, more accurately and, above all, more safely with a circular bench saw. A chop saw is ideal for cross-cuts with a limited cutting width. If you are cutting many mouldings, e.g. for interior fittings and flooring, the Chop saws will save you a considerable amount of time. However, its range of functions is limited compared to Plunge-cut saws and Circular bench saws.

Bandsaws vs. compass saws. Both saws fulfil different tasks. A well-equipped woodworking shop should therefore have both. Compass saws are ideal for cut-outs and mobile work, e.g. kitchen assembly. However, it is strenuous to use in the long term (vibrations) and its Cutting height is limited (maximum half saw blade length). Bandsaws, on the other hand, can be used for finer cuts and larger material thicknesses. As Bandsaws run much more smoothly, they deliver clean cutting edges and are less strenuous to work with. They are also suitable for ripping thicker solid wood, which is then levelled and planed. However, internal cut-outs are not possible with a Bandsaws.

Cable or battery? Many hand-held saws and small stationary machines are available corded or with a rechargeable battery. Saws with a cable have the great advantage that they can be used for longer periods of time or for larger projects without the battery running out. However, the cable restricts the range of movement. Saws with rechargeable batteries are much more mobile and can also be used in places without a power connection (construction site, garden, etc.).

Around the Saws

When choosing the right saw, you should also consider the space requirements of saws and the appropriate workshop equipment.

A Japanese saw or handsaw is equally suitable for work in the workshop and for mobile use. In order to achieve reasonable results in the workshop, at least a small table with an attachment clamp, or ideally a planing bench, is useful. With top-mounted pliers, you usually only work from one side, so two square metres of surface area can be sufficient for small parts that have been roughly cut to length beforehand.

If you are using manual or plunge-cut circular saws in the workshop, a saw table or multifunctional table is ideal. As you have to move around the table and also cut larger panels if necessary, the space required here is significantly larger (panel size + 50 cm all round). On the construction site, you can make do with work trestles and a "sacrificial panel". Semi-stationary saws such as Underfloor pull-push saws often come with a fold-out base frame. Extraction for both types of power tools works by means of a mobile hoover, which does not take up much space.

If stationary saws such as Bandsaws or Circular bench saws are used, not only the working area in front of and behind the machine must be considered, but also additional space for the extraction systems and hose routing. Hazardous areas of the machines also play a role in space planning and therefore the space required.