Chisels

-

Woodworking / metalworking

- Saws

- Chisels

- Carving tools

- Axes and hatchets

- Hammers, nails & pry bars

- Planes

- Woodturning tools & lathes

- Rasps & files

- Measuring and inspection tools

- Scribing & cutting tools

- Routing & drilling tools

- Clamps

- Screwdriving tools

- Pliers

- Workshop equipment & tool sets

- Blacksmithing / blade finishing

- Engraving tools

- Leatherworking, papercraft & upholstery tools

- Stone working tools

- Tools for kids

Chisels

EXPERT KNOWLEDGE CHISELS

... indispensable for accurate woodworking!

The result of woodworking with a chisel depends largely on the quality and sharpness of the tool. The iron must hold its edge and be easy to sharpen, the chisel should have a good overall balance and be comfortable to hold. Chisels are available in graduated widths from 4 mm to 40 mm. The most common width is a 20 mm chisel. Most woodworkers use a six-piece set of chisels. There are many colloquial names for chisels, which basically all mean the same tool. These include Skew chisels, wood chisels, Paring chisels and chisels. Some of the names provide information about how the chisels are guided or used.

Just for re-piercing or for driving?

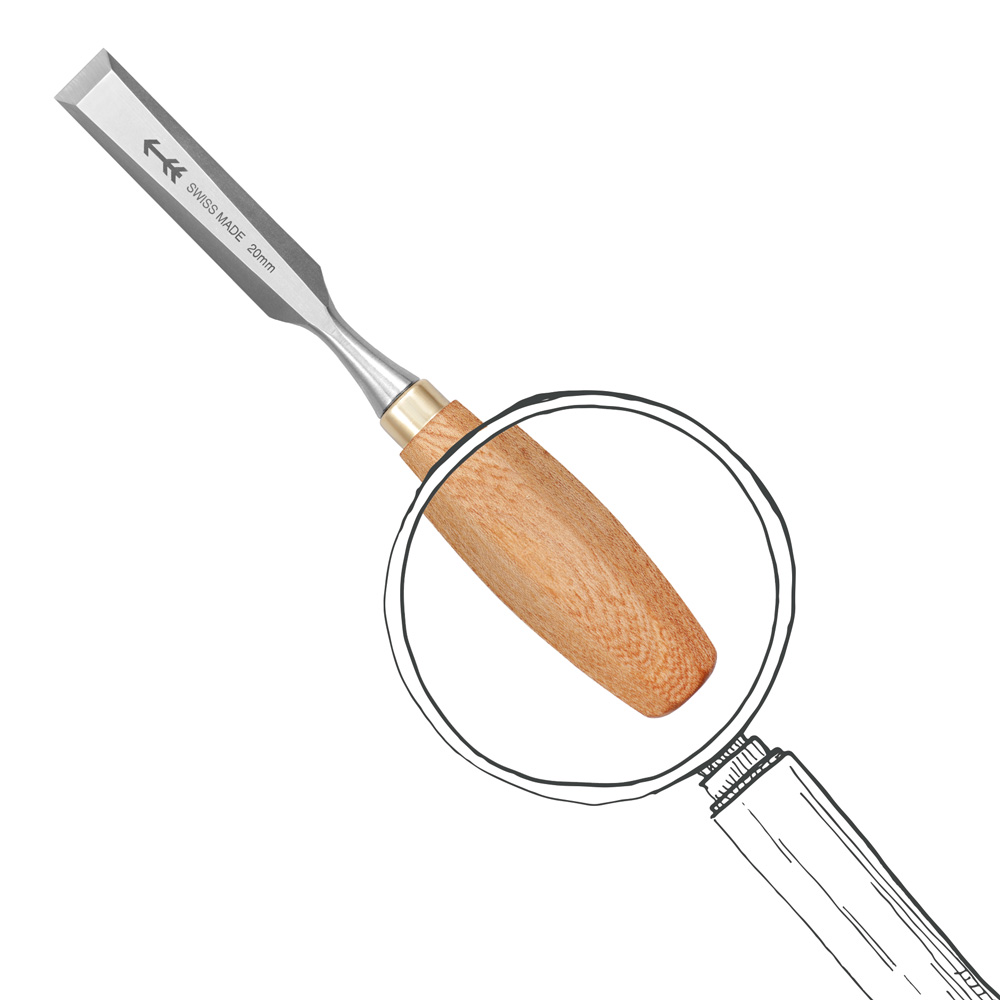

In terms of designation, we differentiate between Paring chisels for light to medium use. They are generally pushed by hand and therefore do not have a steel ferrule at the stapling end.

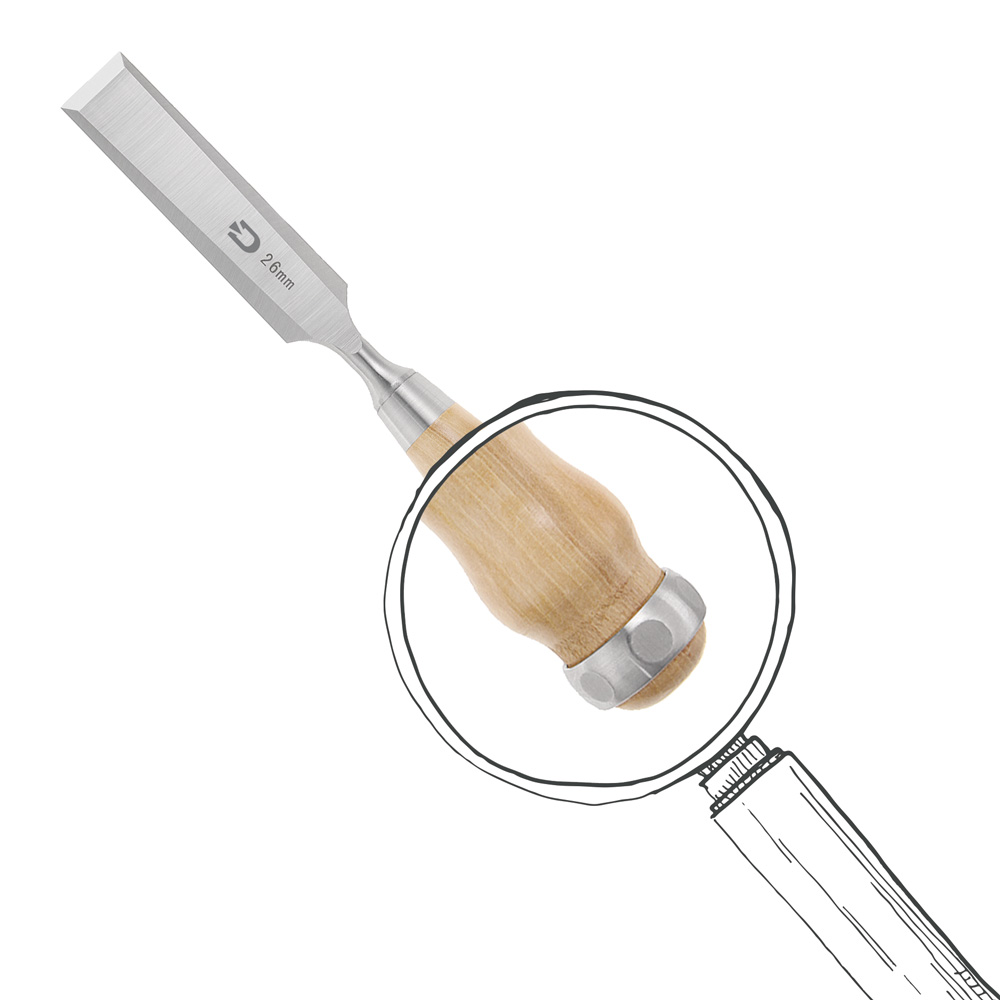

Chisels, on the other hand, are driven with a striking tool (wooden mallets for European irons, iron hammers for Japanese irons). They are therefore more robust in terms of the blade and have a ferrule at the end of the handle.

The traditional English design of the Chisels consists of a shorter blade and an ergonomic handle, which has a thickening at the end of the handle. This can also be driven with the chisel.

Whether with or without a ferrule, the production of the handle from impact-resistant hardwood is a must when driving the iron with the mallet. The handle is often made of hornbeam, but elm or ash are also suitable handle materials.

What designs are available?

Chisels with tang:

Classic design that ensures the blade is firmly anchored in the handle. Cheap products without additional securing of the tang by a ferrule can cause the handle wood to splinter under large impact loads. The clamps can either be made of sheet metal (e.g. Stubai, Pfeil) or solid steel (e.g. DICTUM chisels). The advantage of solid steel is particularly noticeable with frequent use (beard formation at the end of the handle) or when changing the handle (removability).

Chisels with spout:

This rare design enables a smooth transition from the neck to the handle and therefore comfortable ergonomics. The tapered fit of the handle on the Chisels allows large forces to be transmitted when striking. Lateral forces (working out mortises and the like) can cause the handle to loosen. As the taper transmits the impact force and not the rear edge of the spout, there is a small gap between the spout and the handle.

Japanese Chisels:

Japanese chisels are also known as Nomi. Their design combines the advantages of the two adjacent types, i.e. the high power transmission via the cone on the one hand and the firm anchoring of the handle with a tang on the other. Here too, there should be a small gap between the gouge and the handle to ensure that the cone fits snugly (see diagram centre).

Seat of the steel ring on Japanese Chisels

The steel ring transmits the impact force via the cone. If the ring is in contact with the turned transition, some wood should be removed from the contact surface so that the force is not transmitted via the cone but via the contact surface.

The transition between the steel ring and the forged shoulder is ground over by the Manufacturer. If the steel ring loosens slightly, it looks as if the chisel has cracked. However, this is merely a slight compression that occurs when the steel ring is driven together with the blade. Due to the uneven deformation of the steel ring edge, the ring only fits in one position. However, this visual irregularity does not affect the stability of the iron in any way.

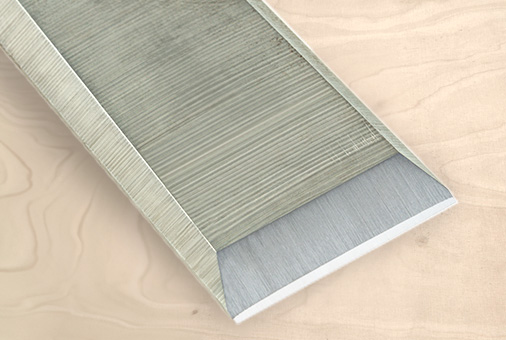

How are chisels ground or sharpened?

The sharpenability varies depending on the steel used. Western chisels are usually made of high-alloy tool steel, e.g. chrome/vanadium steel with a hardness value between 60 and 62 HRC. Many manufacturers, including Pfeil, Kirschen or Stubai, do not specify the steel designation, but use terms such as "special tool steel". Japanese chisels made from low-alloy carbon steel have a value of 62-63 HRC. Chisels made from HSS (short for High Speed Steel) have the highest hardness and toughness with a hardness value of 63 to 64 HRC. To put it simply, the greater the hardness, the longer the iron stays sharp, but the harder it is to sharpen.