Japanese knives (Hocho)

Japanese knives (Hocho)

- Original japanische Messer (Hocho)

- Welcher Messertyp ist für welche Anwendung geeignet?

- Auswahlberatung Japanmesser - Welches japanische Messer kaufen?

- Was macht ein japanisches Kochmesser aus?

- Japanische Messer - Vorteile von Kohlenstoffstahl

- Was bedeutet »nicht rostfrei« bei japanischen Messern und Klingen?

- Was ist der Unterschied zwischen Patina und Rost?

- Was bedeutet »rostfrei« beim Kochmesser?

- Was ist HRC?

- Stahlqualitäten von Japanmessern (Hocho)

- Japanische Messer - Geschmiedet oder gestanzt?

EXPERT KNOWLEDGE JAPANESE KNIVES (HOCHO)

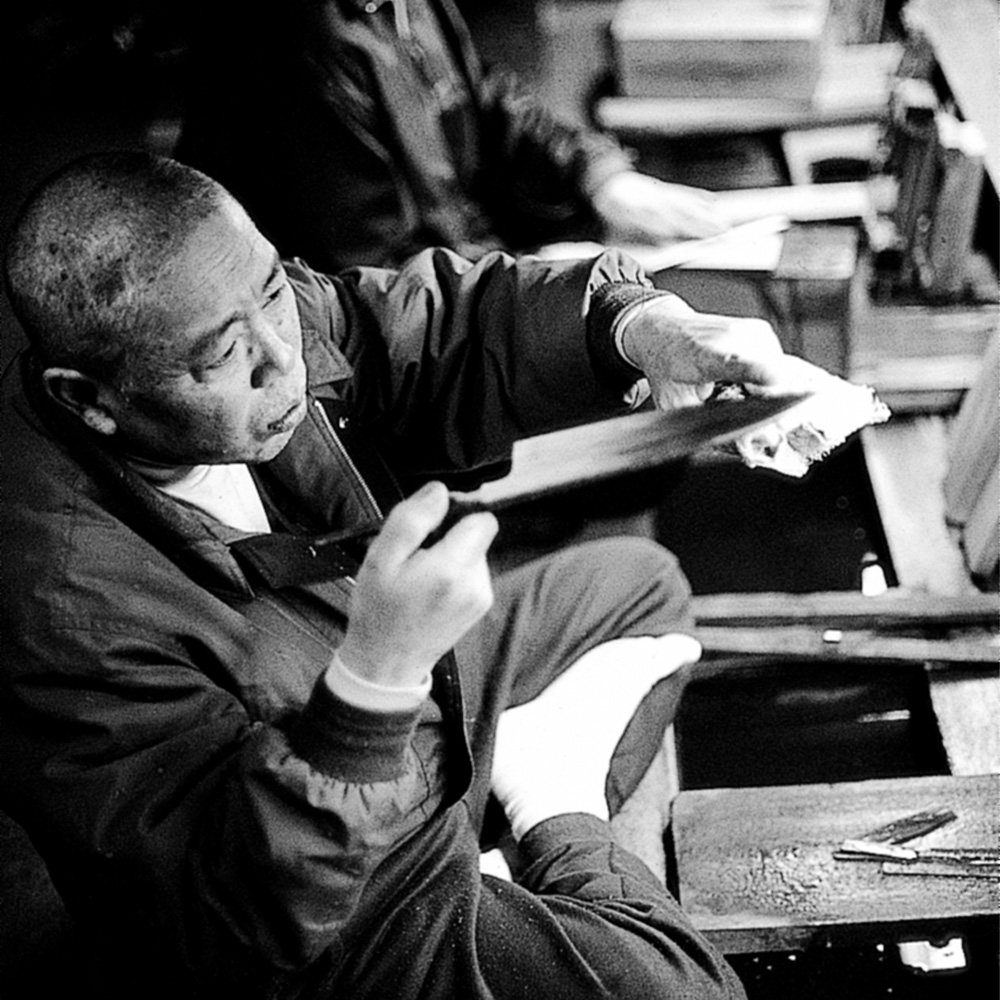

Master Shigefusa

Quality in the kitchen starts with cutting!

In Japan, cooking is understood to be the "art of cutting". Accordingly, the HOCHO is a highly sensitive and extremely sharp tool that demands respectful handling. The blade consists of several layers of steel, whereby the cutting edge is particularly hard and therefore relatively brittle. You should therefore avoid any bending, impact or leverage stress on the blade. The Japanese knives are not suitable for cutting hard foods such as frozen food, bones, bread crusts, etc. Avoid tilting and work with straight, drawn cuts. Rough handling can lead to chipped edges.

Original Japanese knives (Hocho)

For centuries, small Japanese workshops have been producing outstanding kitchen knives with traditional blade shapes using traditional methods - often with a high degree of craftsmanship or even entirely by one hand. For Japanese kitchen knives of this classic shape are called "wabocho". Connoisseurs appreciate them for precisely this reason: the best steels, selected materials for the handle and ferrule, high quality workmanship, original design - and last but not least, of course, for their extreme sharpness and edge retention. For the blades, a hard carbon steel core is usually welded with one or more layers of iron in the forge - similar to the multi-layered swords of the samurai. Traditional materials and shapes are also used for the handle.

Which type of knife is suitable for which use?

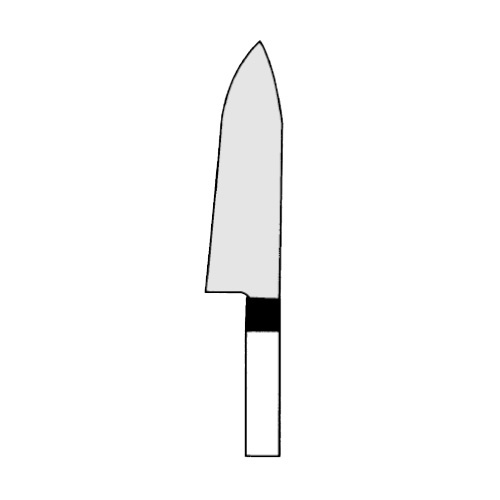

Santoku knives (all-purpose knives)

Santoku are all-purpose knives for meat, fish and vegetables (Santoku = the three virtues). Wide blade for good guidance on the back of the finger. Link: Expert knowledge - Santoku knives

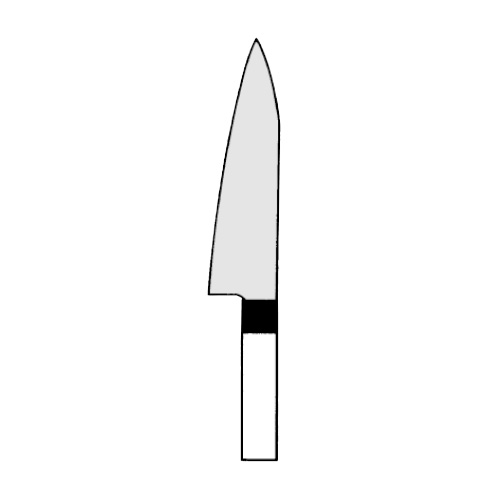

Gyuto knife (meat and fish)

The Gyuto is a versatile Japanese chef's knife for slicing, filleting and preparing fish and meat. Slim blade shape for finer work, pulling or pushing cut. Link: Expert knowledge - Gyuto knife

Usuba knife (vegetables)

The Usuba is a single-edged Japanese vegetable knife with a straight cutting edge for clean slicing on the cutting board, wafer-thin slices are no problem even with ripe tomatoes. Wide blade for good guidance on the back of the finger. Not to be confused with the Double bevelled Nakiri. Link: Expert knowledge - Usuba knife

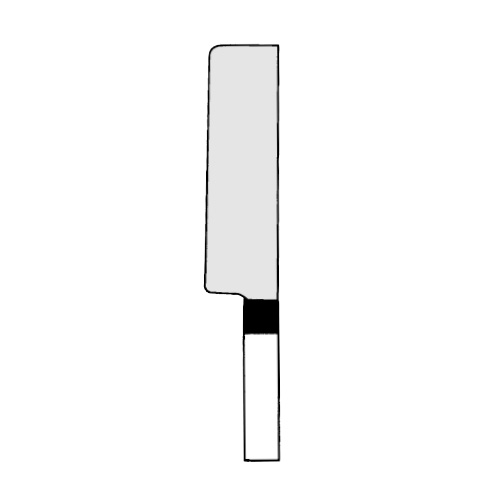

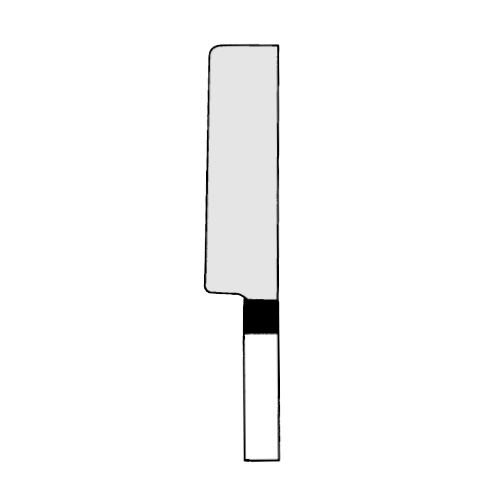

Nakiri knife (vegetables)

The Garde is a vegetable knife sharpened on both sides with a straight cutting edge for clean slicing on the cutting boards, wafer-thin slices are no problem even with ripe tomatoes. Wide blade for good guidance on the back of the finger. Link: Expert knowledge -Nakiri knife

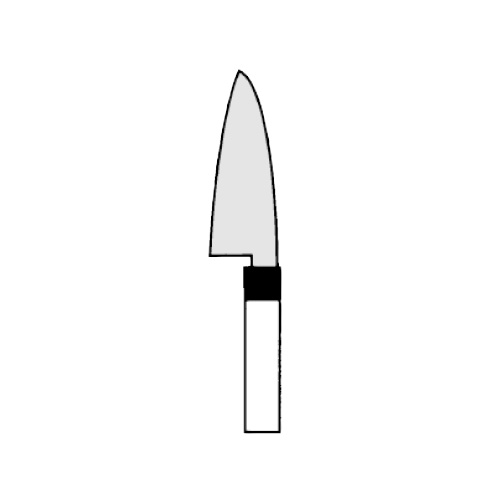

Ajikiri knife (fish and vegetables)

For small fish and for cleaning vegetables and salads, also for weighing herbs. Link: Expert knowledge - Ajikiri knife

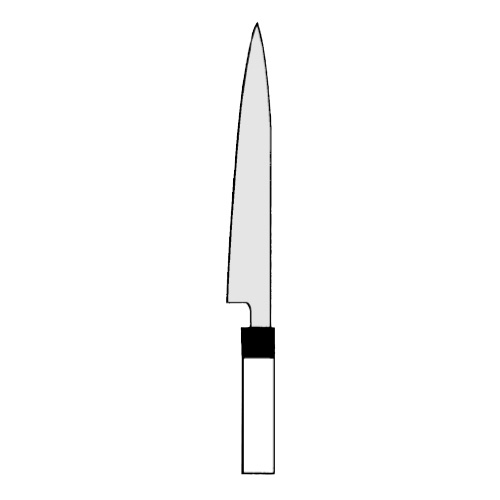

Sashimi knife (fish)

For slicing and filleting fish or ham with a pulling cut. Slim blade in willow leaf or katana or sword shape. Link: Expert knowledge - Sashimi knives

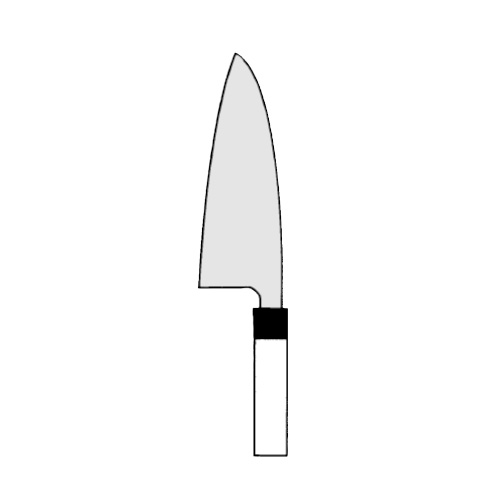

Deba (fish and chopping knife)

Traditional Japanese chef's knives for cutting fish and light chopping work. Thick-walled blade with a wide blade. The back of the blade is used for cutting through thin bones. Link: Expert knowledge - Deba knife

Petty knife (small all-purpose knife)

Small all-purpose knife for fruit, shawls and smaller cutting jobs. Link: Expert knowledge - Petty knife

Advice on choosing Japanese knives - Which Japanese knives to buy?

After the intended use (vegetables, fish, meat, etc.), the amount of care you are prepared to put in is also decisive when choosing the right knife.

How easy a tool is to care for essentially depends on the blade steel and the handle construction:

Blade steel

- Classic carbon steel (single or multi-layer) is not rustproof. The blade must therefore be dried and oiled regularly after use. However, it achieves the highest sharpness and is easy to sharpen.

- Carbon steel as the cutting layer, embedded in stainless steel (three or more layers). The blade is predominantly Rustproof, only the exposed cutting edge area can oxidise. A good compromise between maintenance and sharpenability with the same sharpness.

- "Rustproof stainless steel (stainless steel, single or multi-layered) The blade is Rustproof and does not need to be oiled. However, due to the high chrome content, there are compromises in terms of sharpenability (chrome clogs the Grinding stones and causes a strong burr formation).

Handle

- Classic design with attached wooden handles: can swell when wet and thus loosen (tighten again with a light tap). The knives must be kept dry.

- Construction with continuous tang and handle scales (integral or semi-integral construction): generally less sensitive, depending on the Material. However, this design has a centre of gravity that is shifted backwards and is generally heavier than the classic design.

What makes a Japanese chef's knives?

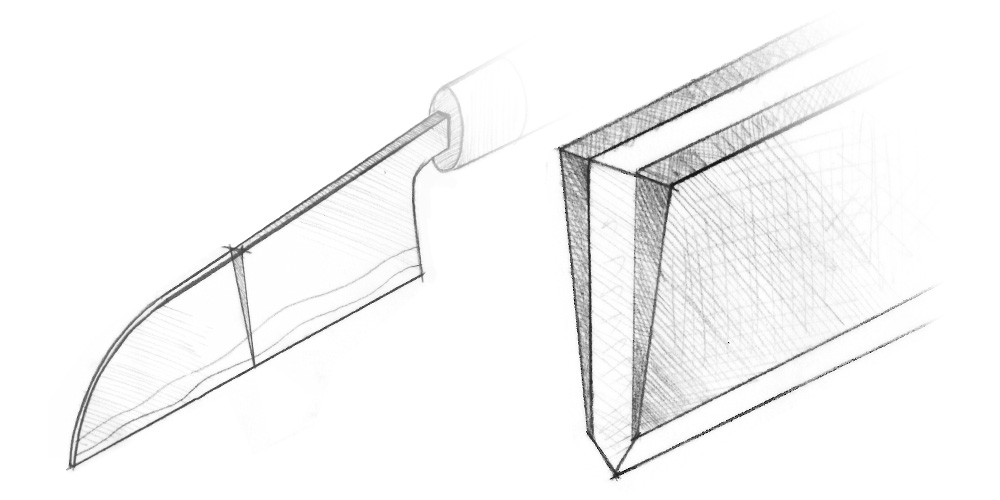

Traditional Japanese knives are made up of several layers and types of steel. The middle layer is usually a very hard, fine-grained carbon steel. The fact that the carbon steel has such a fine structure - experts refer to it as a martensite structure - means that it can be sharpened to a high degree.

However, the disadvantage of this fine matrix is that the steel is hard and brittle and therefore breaks easily. This is also the reason why Japanese knives are made up of several layers. A hardness layer, which is easy to sharpen, is supported by softer outer layers.

Japanese knives - advantages of carbon steel

The cells are cut cleanly with a sharp cut and not pressed or crushed as with a blunter blade. All the flavours in the food are retained. In the case of onions, sharp blades have the advantage that very little juice escapes from the slices. It is mainly the essential oils they contain that cause the tears when cutting onions.

- Less effort required when cutting

- Blades stay sharp for longer and are very easy to sharpen

- Blade shapes are wide, the rear cutting edge remains sharp

- The entire cutting length can be utilised; this is just as advantageous for cradle cutting as it is for filleting.

The choice between a Rustproof and a non-rustproof Kitchen knives depends on the requirements.

For maximum sharpness, as required for Razors, Sushi or Filleting knives and Japanese chef's knives (Hocho), as well as for very stable cutting edges, e.g. for Hunting Knives, non-stainless steel is recommended. This enables a fine cutting edge and a robust edge.

If, on the other hand, medium-level durability is required, such as for work knives, rescue knives or outdoor knives, or if Rustproof is required (outdoor, Hunting), stainless steel with sufficient chromium and carbon is the better choice. This ensures the desired sawing effect and a hardness of at least 58 HRC.

What does "not Rustproof" mean for Japanese knives and blades?

"Not Rustproof" for knives and blades made of carbon steel means that this steel alloy, consisting of iron and carbon, enables particularly sharp and durable blades. However, it is susceptible to acids and moisture. After use, the knives should therefore be rinsed under a jet of water and dried.

Carbon steel shapes a grey patina on the blade, which serves as natural rust protection.

This patina protects against rust formation as long as the knife is properly cared for. If the knife is stored for a long time or in a damp environment, it is advisable to treat it with food-safe blade oil(Sinensis camellia oil) (link) to prevent rust formation.

What is the difference between patina and rust?

If patina has formed on knives that are not so resistant to rust, you could almost think that it is rust? However, it's not that simple.

Patina is a thin layer that forms on the blade and is finished at some point. Rust, on the other hand, simply won't give up and eventually attacks the steel. The line between the two is thin, but patina is really more controlled than rust.

What does "Rustproof" mean for chef's knives?

"Rustproof" is not actually an exact term, as no type of steel is completely rustproof, but rather rust-resistant.

However, the use of the term has become commonplace. Steel is alloyed with at least 13% chromium to protect it from acids and moisture, which is particularly advantageous for outdoor knives or diving knives, for example. The chromium carbides in steel shape a stable structure, but the edge can break out more quickly on thinly ground blades.

Non-rustproof steels generally have a more stable cutting edge than chrome steels. To counteract this effect, the cutting edge should not be ground too thin and the Angle should be adjusted during grinding depending on the load.

Rustproof knife blades act micro-fine like a saw and retain a good utility sharpness in the pull cut, even if the razor sharpness fades more quickly. They are resistant to rust and retain a neat appearance even after Lengthy use.

There are also Rustproof knife steels with low carbon, which do not have the sawing effect but can be ground thin like non-rustproof carbon steels. The disadvantage, however, is that the low carbon content means that the steel does not become as Hardness, which can impair edge retention.

What is HRC?

HRC is an abbreviation for the Rockwell hardness test. There are several hardness testing methods that were developed by the American engineer and company founder Stanley Rockwell in 1920 and which specialise in certain Ranges of application.

A normal kitchen knife blade made of stainless steel usually has 52 to 56 HRC, a high-quality chef's knife made of stainless steel 58 to 61 HRC, blades made of Shirogami up to 65 HRC - and blades made of Aogami reach a hardness of up to 67 HRC.

Steel qualities of Japanese knives (Hocho)

Highest quality: not Rustproof!

In Japan, the Hitachi company produces special cutting steels that represent the highest standard in the world and are used in almost all of the Hocho we offer. These Yasuki Special Steels (YSS), named after their place of origin, are made from iron sand, the same raw material from which the legendary samurai swords were produced. They are characterised by the highest purity in their structure and therefore the highest achievable cutting sharpness.

There are different variants of this steel, depending on the intended use:

- White paper steel (unalloyed carbon steel)

This type of steel is particularly hard and has a particularly fine martensite structure. It can therefore be ground to an exceptionally sharp edge and retains this sharpness over a long period of time. However, it is susceptible to oxidation, i.e. rust. - Blue paper steel

The low-alloy, rust-resistant blue paper steel represents a compromise. Oxidation is prevented on original Japanese knives made from this material by treating them with acid-free, food-safe oils (e.g. camellia oil) (link). - PM steels

Powder-metallurgically produced steels (so-called PM steels) are now also used for knives with a Western design, which are even harder than low-alloy steels and are also Rustproof.

However, they cannot be ground as finely as white paper steel.

Japanese knives - Forged or stamped?

When forging by hand, the workpiece is carefully formed and always kept within the optimum temperature range. The impact force and frequency are controlled as required. This means a forming process that also has a positive effect on the crystalline structure of the metal: the microstructure becomes finer, which improves the mechanical and chemical properties of the steel. Forged blades can be recognised above all by the fact that the thickness of the blade spine increases towards the tang. This makes the blade more resilient and improves the balance.

Machine forging usually involves a few forming operations, which requires significantly higher temperatures than hand forging - high heat has a negative effect on the microstructure.

Production of a hand-forged knife made from Damascus steel is one of the most impressive masterpieces of craftsmanship. Structure de la lame knives combine different steels, and thus their properties, to create a new alloy that can be perfectly customised for the specific application.

Unfortunately, the term "Damascus steel" is often misused for inferior welded composite laminates that have little to do with genuine Damascus steel.

Produkcja Blade structure is often produced in so-called "monster packages".

This involves heating a large damascus package under inert gas, welding it, sawing it and shaping it into sheets. This type of blade structure, known as "superclean" or "ultraclean", offers perfect welded joints and high purity. However, this type of blade structure lacks the ability to be hand-forged to the customer's individual requirements and the function of the knife.

The quality and origin of the damascus are crucial, as industrial damascus may not offer the desired steel properties.

Only if all five criteria are met is a damask Japanese knife worth its price.

- The properties of the steels in the damascus should complement each other and match the intended use. Straightforward lies are often told about low-priced Damascus steels from abroad, with some steels being passed off as high-quality components.

- The arrangement of the steels in the Damascus steel and the mixing ratio should be selected according to the requirements. The number of layers is also crucial.

- The steel structure must be optimised through precise heat treatment.

- Small welding defects can occur in Structure de la lame steel, but these should be very small and at best barely visible. Watch out for large spots that interrupt the pattern.

- Hardness and tempering of the finished blade should be carried out by an experienced Damascus blacksmith. You can only achieve optimum results if you know the material inside out.

Unfortunately, a hand-forged knife is no different in name from industrial products, as the terms Damascus knife, Blade structure, Damascus steel, Damascus steel, Damascus knife etc. are not protected and anyone is free to interpret and use them as they wish.