Content

Expert Knowledge - Hatchets and axes

There are three basic types to be distinguished:

- Axes and hatchets for cutting

These tools cut the wood fibres, e.g. for chopping down trees, removing branches, or notching. As a rule, such tools have slender double-bevelled blades with a relatively pointed cutting angle to enable easy breaking into the wood.

- Axes and hatchets for splitting

These tools split wood along the direction of the fibres, e.g. for chopping firewood, shingles, split boards, or poles. As a rule, such tools have thick and heavy doublebevelled blades with a relatively blunt cutting angle for high splitting efficiency.

- Axes and hatchets for cutting and splitting

These tools are used for the trimming and smoothing of workpieces and for the production of beams, poles, wood for construction, and wooden joints. As a rule, such tools have slender one-sided bevelled blades. Typical examples are the classic broad axes.

As axes are mostly used outside the workshop, a mobile sharpening device such as the DMT folding diamond sharpener (No. 705391) is recommended. It has two different grits and is extremely wear-resistant. You lay the blade of the axe on a solid support, such as a tree trunk, and guide the sharpener with uniform strokes transversely to the cutting edge, while maintaining the bevel angle.

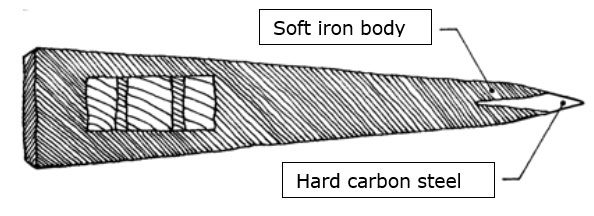

With their laminated forged blades*, Japanese axes are the epitome of the fine art of blacksmithing. The durability and sharpness of the steel along with the well-proportioned axe heads and handles are unmatched!

Features of a Japanese axe:

- Forged double-layered blades - very hard cutting edges of 58- 60 HRC steel and impact-absorbing soft iron body*

- Handle of untreated Japanese white oak

- Handle is set by means of a wooden wedge and an additional metal wedge

- Each axe comes with a handy sheath (*unless otherwise stated)

With their multi-layered forged heads made of a lamination of soft shock absorbing iron and hard high carbon steel (58-60 RC), Japanese axes stand for superior edge-holding and sharpening properties.

There are two basic types of traditional Japanese axe heads:

Ono have a wide beard and a narrow throat, making them excellent for hewing and smoothing wood. The concentration of mass towards the cutting edge improves stability and control during use.

Yoki have a slender long head, making them best suited for splitting boards and chopping wood. Both have unvarnished, Japanese white oak handles.

Nata are machete-like cutting tools equipped with strong, sharp blades forged from multi-layered steel. In Japan, they are mainly used in the garden for limbing and trimming bushes and shrubs. They can also be used for sculpting wood or even chopping food.

»A smith is only as good as the workman who can explain the function of the tool to him«. These high-quality tools are developed in collaboration with our master carpenter and produced in small European forges according to traditional forging techniques.

Features of DICTUM axes and hatchets:

- Forged by hand

- Forged of carbon steel (hardness 56-57 HRC*)

- Practical, tried and tested traditional axe

- Untreated ash handles made and fitted by hand

- Handle is set by means of a wooden wedge (* unless otherwise stated)

Our high-quality axes with practical design are produced in small European forges according to traditional forging techniques.

Features of a DICTUM axe:

- Forged by hand

- Forged of C-60 carbon steel (hardness 56-57 HRC*)

- Practical, tried and tested axe shapes

- Ash handle with a natural Urushi surface for comfortable feel and dirt protection (water-proof, solvent-resistant, extremely ageing-resistant)

- Handle is set by means of a wooden wedge and an additional metal wedge

- Each axe comes with premium leather sheath made of vegetable-tanned cowhide* * unless otherwise stated

Under the motto »An axe is as good as its smith«, the Swedish company Gränsfors Bruks has been manufacturing top-quality axes for over 100 years.

Features of a Gränsfors axe:

- Forged by hand under a spring hammer

- Forged of 56-57 HRC carbon steel

- 20 years warranty on the axe head

- Forger's initials on each axe head

- 20 year warranty on the axe head

- Oiled axe handles of selected hickory

- Handle is set by means of a wooden wedge

- Each axe comes with premium leather sheath

- Includes manual

Wetterlings in Sweden has been making hand-forged axes from premium carbon steel since 1880.

Features of a Wetterlings axe:

- Forged by hand under a spring hammer

- Forged of 56-57 HRC carbon steel

- Lifetime warranty on the axe head

- Oiled handles of selected hickory

- Handle is set by means of a wooden wedge

- Each axe comes with premium leather sheath

Hults Bruk forge in south-east Sweden has been manufacturing premium axes and hatchets since 1697. Having bought the forge, Swedish global enterprise Hultafors is continuing this more than 300-year-old tradition.

Features of a Hultafors axe:

- Forged by hand under a spring hammer

- Forged of 56-57 HRC carbon steel

- Oiled hickory handles

- Handle is set by means of a wooden wedge and an additional metal wedge

- Each axe comes with premium leather sheath