Coping saws

-

Woodworking / metalworking

-

Saws

- Japanese saws with interchangeable blade

- Japanese saw sets

- Saw cases

- Classic handmade Japanese saws

- Japanese folding saws (woodworking)

- Western backsaws

- Bow saws

- Stair saws / groove-cutting saws

- Hand saws / jack saws

- Veneer and flush-cutting saws

- Coping saws

- Compass saws

- Saws for special materials

- Mitre saws

- Saw guides / mitre boxes

- Compact saws / mini saws

- Beam saws

- Saws for dovetails

- Model-making saws

- Outdoor saws

- Branch saws

- Saw-set pliers and sharpening devices for saws

- Spare parts for saws

- Corded saws and cordless saws for wood

- Chisels

- Carving tools

- Axes and hatchets

- Hammers, nails & pry bars

- Planes

- Woodturning tools & lathes

- Rasps & files

- Measuring and inspection tools

- Scribing & cutting tools

- Routing & drilling tools

- Clamps

- Screwdriving tools

- Pliers

- Workshop equipment & tool sets

- Blacksmithing / blade finishing

- Engraving tools

-

Saws

- Leatherworking, papercraft & upholstery tools

- Stone working tools

- Tools for kids

Coping saws

EXPERT KNOWLEDGE COPING SAWS

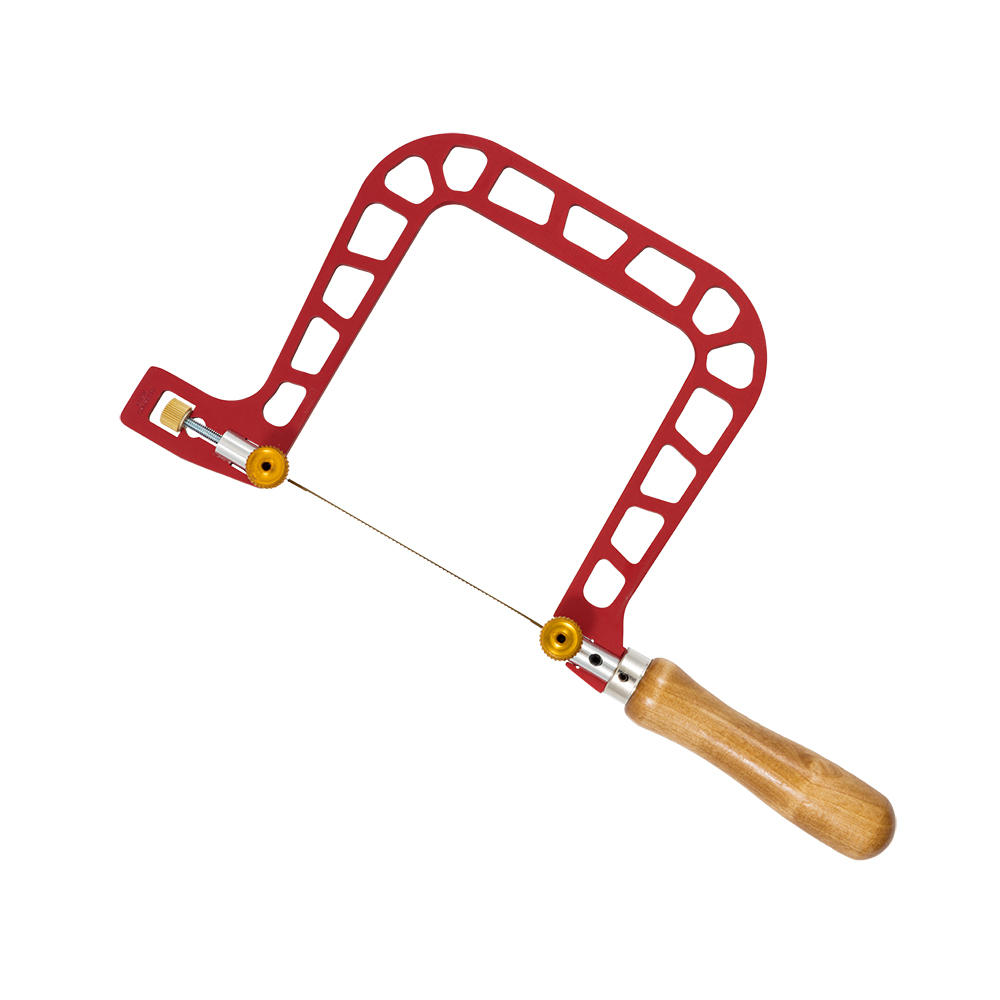

How is a Coping saws constructed?

The basic design of almost all Coping saws is identical. It makes no difference whether you opt for a plastic or wooden handle, a chrome-plated or nickel-plated fretsaw bow with a large or small Throat depth. A Coping saws always consists of a handle to which a U-shaped saw bow is attached. The saw bow, also known as a bow, can have different lengths. The fretsaw blade is clamped between the two ends of the bow. In simple versions, wing nuts are used for fastening. High-quality Coping saws are equipped with clamping screws and levers to enable quick and easy clamping.

How is the fretsaw blade clamped correctly?

Regardless of the clamping mechanism, first clamp your saw blade at one end of the saw bow. It is best to use the side opposite the handle for this. The saw teeth point downwards, i.e. towards the handle. Then press the bow together slightly to be able to clamp the other end of the saw blade. Squeezing the bow is important to give the fretsaw blade the necessary tension.

If children want to clamp the saw blade of a Coping saws on their own, they can use the edge of a table to help them. One side of the blade is supported on this. This allows the fretsaw blade to be brought into the correct position with less effort. The clamping screw can then be tightened with your free hand.

Clamping the saw blade is usually even easier with a very high-quality saw (with a rigid bracket) or a scroll saw, the mechanised version of a Coping saws. Many Manufacturers have solutions with different levers and clamping devices that make clamping easier.

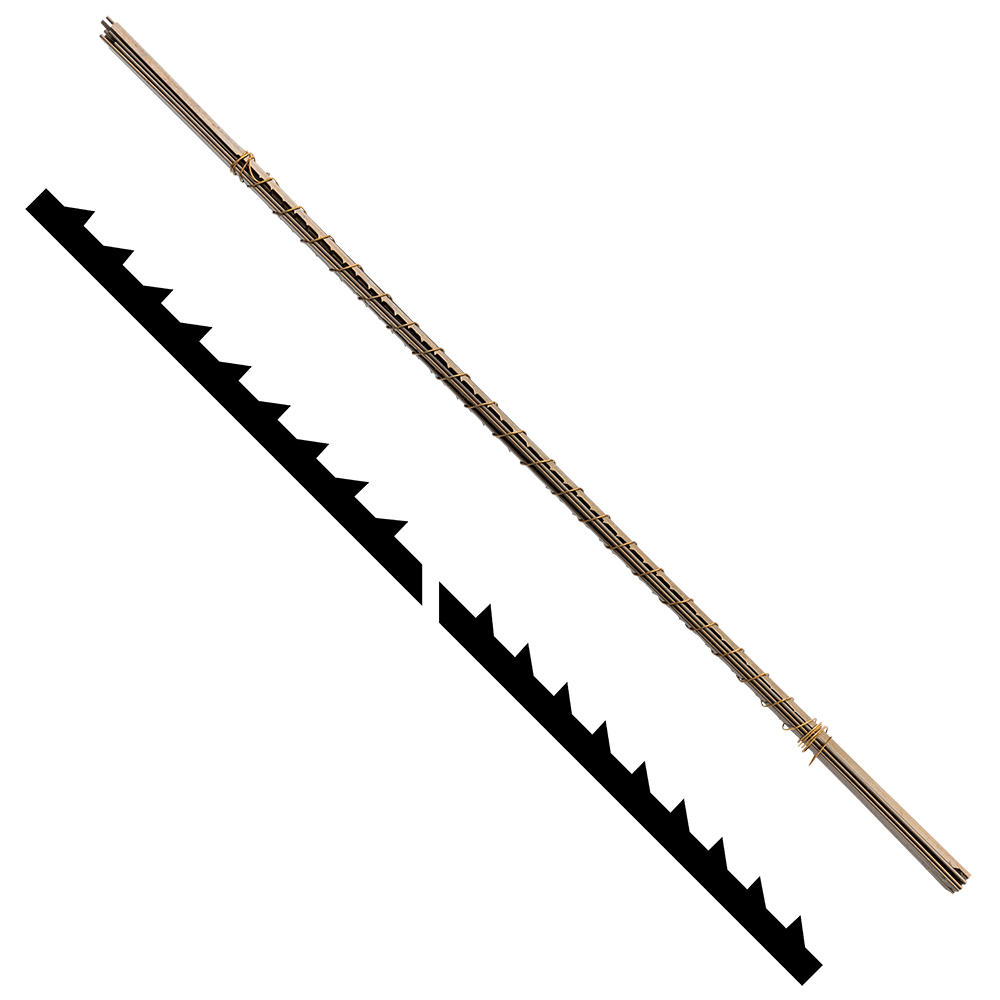

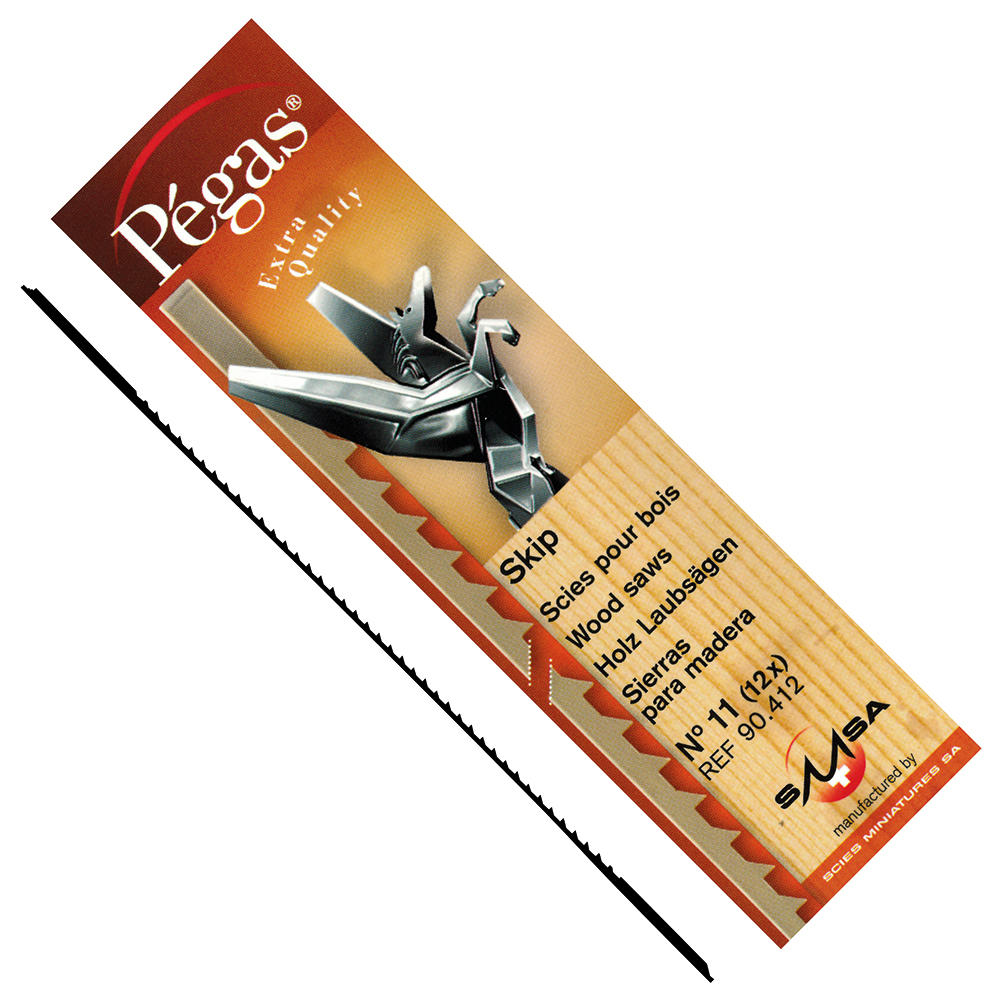

What are the differences between the various fretsaw blades?

There are different saw blades for Coping saws that differ in their properties. Depending on the toothing, different materials can be cut. The following are commonly used for woodworking:

- Fretsaw blades with normal teeth (standard)

- Fretsaw blades with double teeth

- Fretsaw blades with opposing teeth

- Spiral fretsaw blades (serrated all round)

Each of these four blades is suitable for fine work with wood and plastic. However, pay attention to a few other special features of the saw blades when buying: The thicker a saw blade is, the fewer tight curves are possible. On the other hand, thick saw blades are more stable and tear less quickly. The size of the teeth also plays an important role. Larger teeth mean that there are fewer teeth per inch, as the length of the saw blade remains the same. Fewer teeth cut faster and the sawdust is removed more quickly due to the greater distance between the teeth. Spiral-toothed fretsaw blades are ideal for workpieces with many curves and precise corners. You can saw in any direction with an all-round toothed Saws blade. However, bear in mind that such a blade will deviate slightly to the side when making straight cuts and the saw cut will be wider overall. There are also special fretsaw blades for cutting metal and special saw blades for scroll saws. In purely visual terms, however, scroll saw blades are not easy to distinguish from conventional fretsaw blades. Therefore, always pay close attention to the description of the corresponding saw blade.

How can I transfer templates to my workpiece?

For crafting, you can draw your own designs or search the internet for templates for your fretwork. You can draw your design directly onto the plywood surface with a pencil. If you want to use fretwork templates from the internet, you can print them out and glue them on with normal wood glue. However, you will then need to sand the workpiece thoroughly after sawing it out. You can also transfer the printout using carbon paper. Tracing very detailed templates is very time-consuming. Alternatively, apply a little Orange oil to a Scarves and rub a thin layer onto the wooden surface. Then place the copy or laser printout with the printed side on the board and rub the printout lightly. Carefully peel off the printout and allow the Orange oil to evaporate. The toner will dissolve or remain on the wooden surface. Bear in mind that the motif will be transferred mirror-inverted!

Prongs with the Coping saws

There are many ways to create a tine joint. The traditional method starts with sawing the tines and dovetails vertically with a fine saw or Bow saws. The edge dovetails are then set down and the remaining dovetails and tines are finished with a chisel. Others can use a Coping saws for both work steps. The joint can then be sawn vertically and finished horizontally in a single pass. This saves time, avoids tears caused by chiselling and also allows the finest saw kerfs.

What else do I need for fretwork?

- Plywood (poplar) up to a thickness of about 6 mm is very suitable as material for beginners and for handicrafts in general.

- The Saws cuts on traction when moving downwards. The workpiece should therefore rest close to the edge of a table or on a fretsaw board with a V-cut.

- Coping saws are ideal for internal cut-outs. To be able to thread the saw blade, you will need a drill or a hand drill.

- You can find templates and helpful instructions in numerous Books on the subject of fretwork and fine cutting.

- Non-toxic colours (e.g. Linseed oil paints) and stains are suitable for painting your work.

Where does the name "Coping saws" come from?

The Coping saws were developed in Italy around 1560. It was originally used to saw out fine wooden elements for ornate marquetry work, which were then assembled to create a textured and patterned surface. As these inlays were often designed in the shape of foliage leaves, the newly invented saw was given the name "Coping saws". It is still used today to saw curved shapes out of wood, whether for craft projects or creative designs. Coping saws remain a versatile and challenging hobby to this day, as well as a valued form of arts and crafts.