Expert Knowledge - Steel terms

- 1.2067 / 102Cr6 / L3:

-

This ball bearing steel, also known as L3 steel, offers a long service life. Well suited for forge-welding in Damascus structures. Not rustproof. (C = 0.95-1.05 / Si = 0.15-0.35 / Mn = 0.3-0.6 / P < 0.025 / S < 0.025 / Cr < 0.4 / Mo < 0.1 / Ni < 0.4)

- 1.2379 / X153CrMoV12 / D2:

-

Excellent edge retention and sharpness. With a chromium content of 12 %, it still belongs to the rust-resistant steels group. (C = 1.53 / Si = 0.35 / Mn = 0.4 / Cr = 12.0 / Mo = 0.85 / V = 0.85)

- 1.2842 / 90MnCrV8 / O2:

-

High warp-resistance during machining and heat treatment. Can be easily polished and sharpened. Ideal for a Damascus structure with 1.2235 steel (80CrV2). Not rustproof. (C = 0.9 / Si = 0.25 / Mn = 1.95 / Cr = 0.35 / V = 0.15)

- 1.2235 / 80CrV2 / L2:

-

Easy-to-sharpen carbon steel with minor alloy constituents. Ideal for a Damascus structure with 1.2842 steel (90MnCrV8). Not rustproof. (C = 0.75-0.85 / Si = 0.15-0.35 / Mn = 0.3-0.5 / P < 0.025 / S < 0.01 / Cr = 0.4-0.6 / V = 0.15-0.25)

- 1.4112 / X90CrMoV18 / 440B

-

Versatile, very wear-resistant and easy to polish chrome steel. High resistance to rust. Easy to sharpen. Not suitable for forge-welding. (C = 0.93 / Si = 0.5 / Mn = 0.5 / Cr = 18.0 / Mo = 1.1 / V = 0.1)

- Iron (Fe):

-

Does not occur naturally in its pure form (other than in meteorite iron). Obtained by smelting iron oxides (iron ore, magnetite, etc.) it was first produced in Asia approx. 2600 years ago.

- Steel:

-

A forgeable, alloyed or non-alloyed iron with a carbon content (C) of between 0.1% and maximally 1.7%.

- Alloying:

-

The addition of certain metals (e.g. chromium, manganese) to change the characteristics of the base metal.

- Tool steel:

-

Alloyed or non-alloyed steel with a carbon content of at least 0.2%, a level which allows the steel to be hardened.

- Carbon steel:

-

A non-alloyed tool steel with a carbon content of 0.2 - 1.7% which can be sharpened to a very high degree due to its fine grain structure.

- HSS (High Speed Steel):

-

A type of steel which is heat resistant to approx. 570 °C due to a relatively high content of chromium, molybdenum, tungsten and vanadium. Used in machine and turning tool blades.

- ATS 34:

-

A very pure, rustproof carbon steel made in Japan that displays a very fine crystalline structure due to its high molybdenum content. (C = 1%, Cr = 13.5%, Mo = 3.5%, Mn = 0.4%, P = 0.023%, S = 0.003%).

- Silver Paper Steel (Gin Gami, GIN1):

-

Rustproof blade steel made by Hitachi. Particularly corrosion- and wearresistant due to its high chromium content (chromium carbides). (C = 0.9%, Cr = 16%, Mn = 0.6%, Mo = 0.4%, S = < 0.004%, P < 0.025%).

- VG-10 steel:

-

Rustproof high-class blade steel, made in Takefu. Its high content of cobalt and carbides make it extremely durable. (C = 1.0%, Cr = 15%, Mo = 1.0%, V = 0.2%, Co = 1.5%).

- Multilayer steel:

-

In contrast with monosteel blades that consist entirely of one material, blades made of multilayer steel have a layered construction that is laminated by so-called forge welding.

With this method, a high carbon core of temperable hard steel ensures the superior sharpness and excellent cutting properties of Japanese knives. This middle layer is protected by a coat of softer steel or iron (with a lower carbon content) that cannot be tempered. This coat is forge-welded to the core in one or more layers, giving the knife formidable tensile strength.

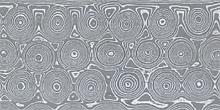

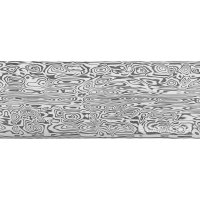

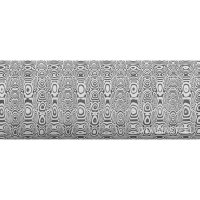

- Damascus steel:

-

Named after Damascus, the ancient centre of the metalworking trade, this steel is wellknown for its highly grained surface. First produced in India around 300 BC. The unique structure was originally created using steel segregation techniques during cooling (to make what was known as Wootz steel). In modern Damascus steels, this structure is created by forge welding and folding steels of different carbon contents together.

(Most commonly used combination: Carbon Steel 1095 / Nickel Steel 15N20)

The combination of carbon steel 1095 (“dark”) and nickel steel 15N20 (“bright”) ensures optimum contrasts when forging Damascus steel.

Carbon steel 1095: (C = 1 / Mn = 0.5 / P < 0.04 / S < 0.05 Nickel steel 15N20: C = 0.75 / Si = 0.3 / Mn = 0.4 / P < 0.02 / S < 0.10) - Suminagashi steel:

-

A Japanese variation of Damascus steel that contains a carbon steel core, in contrast to European Damascusblades.

- White Paper Steel (Shiro Gami):

-

Trade name for a type of highly pure carbon steel made by the Hitachi Company that is smelted from iron sand (Masa) and is of particularly high quality, mainly used for making cutting tools. (C = 1.2%, S < 0.004%, P < 0.025%).

- Blue Paper Steel (Ao Gami):

-

Similar to White Paper Steel but alloyed with an additional 0.4% chromium and 1.8% tungsten. This makes it somewhat tougher.

- Tamahagane:

-

Japanese sword steel produced from iron sand (Masa) smelted in a charcoal fired furnace. This process, called "Tatara", is the earliest known method (approx. 1800 years old) in which steel can be obtained directly from the raw material without any intermediate steps. It yields steel with the highest possible degree of purity.

- Sintered steel:

-

Sintering allows metals which normally cannot be alloyed or welded together to be combined. The components are mixed in powdered form and then hot isostatically pressed in a process known as Powder Metallurgy (PM). The Swedish Damasteel AB company has used this technique since 1995 to produce rustproof Damascus steel with an extremely fine martensitic structure. The steel, called RWL 34, contains 1% C, 14% Cr, 4% Mo and 0.2% V. It displays excellent sharpening properties, is extremely tough and very resistant to wear, making it ideal for use in the blades of outdoor knives.

- Cowry X:

-

Stainless heavy duty steel made using the powder metallurgy process. (C = 3%, Cr = 20%, Mo = 1%, V = 0.3%, HRC 65-67).

- SG-2:

-

Stainless heavy duty steel made using the powder metallurgy process. (C = 1.3%, Cr = 15%, Mo = 3%, V = 2%, HRC 63-65).

- SKD 11:

-

High-alloyed Japanese tool steel, which was originally developed for the use of machine tools. Due to its high percentage of carbide it is very abrasion resistant, durable and non-corroding but not rust-proof.

- YC-3:

-

Japanese carbon steel similar to White Paper Steel but not as pure. The cutting edges are less likely to chip out and forging is easier. (C = 1.1%, S < 0.03%, P < 0.03%)

- VG-10 Steel:

-

Rustproof high-class blade steel, made by Takefu (Japan). Extremely tough and durable due to high content of cobalt. (C = 1% / Si = 0.6% / Mn = 0.5% / P < 0.03% / S < 0.03% / Co = 1.5% / Cr = 15% / Mo = 1% / V = 0.2%)

- Böhler N690:

-

Stainless steel with cobalt, molybdenum and vanadium. Finely structured, tough and wear resistant steel. (C = 1.05% / Si = 0.4% / Mn = 0.4% / Co = 1.5% / Cr = 17% / Mo = 0.5%)

- VG-1 Steel:

-

Rustproof steel, made by Takefu (Japan). Enhanced toughness due to its nickel content. (C = 0.95% – 1.05% / Si < 0.5% / Mn < 0.5% / P < 0.03% / S < 0.03% / Cr = 13% - 15% / Mo = 0.2% – 0.4% / Ni < 0.25% / Cu < 0.25%)

- SLD:

-

Japanese steel made by Hitachi which guarantees excellent sharpness and wear resistance due to its high carbon content. This steel features a chrome content of 12 % and is therefore designated as a so called rust-resistant steel. (C = 1.5% / Si = 0.25% / Mn = 0.4% / Cr = 12% / Mo = 1% / V = 0.35%)

- Sandvik 12C27:

-

Stainless blade steel made in Sweden. The company Sandvik continuously improved this steel over a period of 45 years which evolved the 12C27 steel into the high performing steel grade it is today. It is very popular for making hunting and folding knives. (C = 0.6% / Si = 0.4% / Mn = 0.4% / P = 0.03% / S = 0.01% / Cr = 13.5% / Mo = 3% / V = 2%)

- Sandvik 19C27:

-

Swedish blade steel made by the company Sandvik. A stainless steel with a high content of carbon, very good wear resistance. (C = 0.95% / Si = 0.4% / Mn = 0.65% / P = 0.025% / S= 0.01% / Cr = 13.5%)

- CPM S35VN:

-

A powder-mettalurgically manufactured premium knife steel. The steel has an excellent combination of wear and corrosion resistance. (C = 1.4% / Cr = 14% / Mo = 2% / V = 3% / Nb = 0.5%)

- C-75:

-

Spring steel with high carbon content, easy to re-sharpen. (C = 0.75% / Si = 0.25% / Mn = 0.7%)

- Damasteel:

-

Rustproof, powder-metallurgically manufactured Damascus steel, composed of RWL-34 (“bright”) and PMC-27 (“dark”). (RWL-34: C = 1.05% / Si = 0.5% / Mn = 0.5% / P = 0.05% / S=0.03% / Cr = 14% / Mo = 4% /V = 0.2% PMC-27: C = 0.6% / Si = 0.5% / Mn = 0.5% / Co = 13.5%)

- RWL-34:

-

Rustproof, powder-metallurgically manufactured steel, made by DAMASTEEL (Sweden) on the basis of the popular knife steel ATS34. The powder-metallurgical manufacturing process allows for a precise chemical composition. (C = 1.05% / Si = 0.5% / Mn = 0.5% / P = 0.05% / S = 0.03% / Cr = 14% / Mo = 4% / V = 0.2%)

- 440 Steel:

-

Is a description for stainless steels which are often used in the knife making industry and which are separated in three categories. The steels 440A, 440B (1.4112) and 440C (1.4125) differ by a higher content of carbon.

440A: (C = 0.7% / Si = 1% / Mn = 1% / / P = 0.04% / S = 0.03% / Cr = 17% / Mo = 0.75%)

440B: (C = 0.85% / Si = 1% / Mn = 1% / / P = 0.04% / S = 0.03% / Cr = 17% / Mo = 0.75%)

440C: (C = 1% / Si = 1% / Mn = 1% / / P = 0.04% / S = 0.03% / Cr = 17% / Mo = 0.75%) - AUS Steel:

-

The Japanese, stainless steels AUS-6 and AUS-8 are comparable to the European 440 steels concerning their characteristics. These steels are mainly differing from the content of carbon.

AUS-6: (C = 0.6% / Si = 1% / Mn = 1% / P = 0.04% / S = 0.03% / Cr = 14% / V = 0.2% / Ni = 0.49%)

AUS 6 M: Similarly to "Silver Paper Steel", just slightly softer. (Cr= 14%, C= 0,6%, Mo = 0,2%, V = 0,2%)

AUS-8: (C = 0.7% / Si = 1% / Mn = 0.5% / P = 0.04% / S = 0.03% / Cr = 14% / Mo = 0.2% / V = 0.2% / Ni = 0.49%) - PM Steel

-

Sintering allows metals which normally cannot be alloyed or welded together to be combined. The components are mixed in powdered form and then hot isostatically pressed in a process known as Powder Metallurgy (PM). These rustproof steels even outreach low alloyed steels in terms of hardness. However, they cannot be grinded as fine as low alloyed carbon steels (e.g. White Paper Steel).

- Carbon Steel 1095:

-

Carbon steel 1095 has a fine-grained structure and therefore features excellent sharpening qualities. Ideal for forge welding, it is often used for Damascus blades. (C = 1% / Mn = 0.5% / P < 0.04% / S < 0.05%)

- Hardening:

-

Heating hardenable steel to above the transformation point (approx. 780 °C for carbon steels, approx. 1050 °C for rustproof steels, depending on the alloy) and subsequently quenching them (in water, oil or air) results in the formation of a new, finer crystalline structure. The steel gets harder, more brittle and more sharpenable because of the finer structure. The hardness can be tested using the Rockwell method (pressing a diamond cone into the surface of the steel).

- Annealing:

-

After hardening, the steel must be annealed to avoid brittleness. In general, the steel is heated in a controlled manner (for a specific time at between 180 and 300 °C) to remove the internal stresses in the structure. In the process, the steel becomes somewhat less hard, but gets tougher and less prone to chipping. It is important to note that the properties exhibited by an individual blade do not solely depend on the chemical composition of the steel used. The blacksmith's skill and the nature of the hardening process employed also play a very important role in the quality of the outcome. Careful forging, for example, further refines and homogenises the steel's structure. Prolonged heating during the forging, hardening or annealing process lead to carbon diffusion that diminishes the hardness and edge life of the blade. Impurities (e.g. P, S) have a very detrimental effect on the blade and cause a dramatic increase in the brittleness of the edge.

C

Carbon

Mo

Molybdenum

Si

Silicon

V

Vanadium

Mn

Manganese

W

Tungsten

P

Phosphorus

Ni

Nickel

S

Sulfur

Cu

Copper

Co

Cobalt

Nb

Niobium

Cr

Chromium

Note:

It is important to note that the properties exhibited by an individual blade do not solely depend on the chemical composition of the steel used.

The blacksmith's skill and the nature of the hardening process employed also play a very important role in the quality of the outcome. Careful forging, for example, further refines and homogenises the steel's structure. Prolonged heating during the forging, hardening or annealing process lead to carbon diffusion that diminishes the hardness and edge life of the blade. Impurities (e.g. P, S) have a very detrimental effect on the blade and cause a dramatic increase in the brittleness of the edge.