Lathes

-

Woodworking / metalworking

- Saws

- Chisels

- Carving tools

- Axes and hatchets

- Hammers, nails & pry bars

- Planes

-

Woodturning tools & lathes

- Lathes

- Lathe accessories

- Extraction devices for lathes

- Clamping tools

- Woodturning jackets / protective equipment

- Woodturning gouges / turning tools by manufacturer

- Woodturning surface treatment

- MT adapters, reducing sleeves, ASR locking rings

- Turning kits

- Special tools for pen turning

- Spare parts

- Special tools for woodturning

- Measuring instruments for woodturners

- Turning tool sets

- Hollowing tools

- Drilling tools for woodturners

- Accessories

- Woodturning gouges / turning tools by design

- Tool / lathe bed maintenance

- Rasps & files

- Measuring and inspection tools

- Scribing & cutting tools

- Routing & drilling tools

- Clamps

- Screwdriving tools

- Pliers

- Workshop equipment & tool sets

- Blacksmithing / blade finishing

- Engraving tools

- Leatherworking, papercraft & upholstery tools

- Stone working tools

- Tools for kids

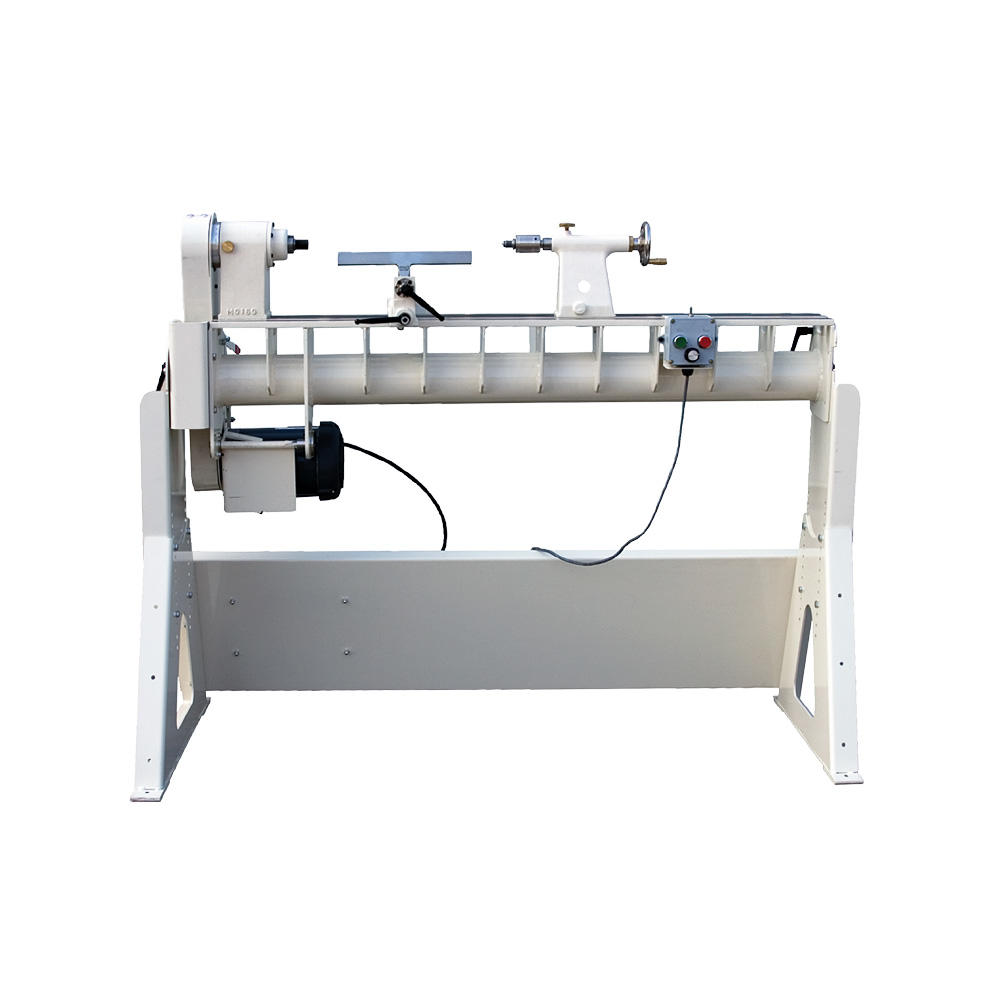

Lathes

EXPERT KNOWLEDGE - LATHES

Which Lathes to buy? How to find the right woodturning lathe!

It is not easy to find a lathes that meets your individual requirements. Straight for less experienced woodturners, the range of lathes on offer seems huge and the differences often lie in the details. Here is an overview of the terms used and the key features of Lathes.

Important parameters of a Lathes

- The Centre height of a lathe is the distance from the bench bed to the centre of the spindle and indicates the maximum turning diameter up to which a workpiece can be machined (double Centre height). Centre heights are usually approx. 175 mm for bench lathes and 200 to 300 mm for solid floor models.

- The Distance between centres refers to the distance between the centres of the headstock and Tailstock and indicates the maximum Length you can machine. The Distance between centres is usually infinitely adjustable by moving the Tailstock. Small table models offer a maximum Distance between centres of 350 mm, while larger machines can hold workpieces up to a Length of 900 mm and more (without extension).

While the Distance between centres can be extended relatively easily on many Lathes by extending the bench bed, the Centre height can only be extended on very few machines or only with great effort. To turn larger diameters, the headstock can therefore be rotated on some Lathes or the lathe offers additional clamping options on the outside (external turning option).

- The Speed or Speed ranges of a Lathes indicates the number of revolutions per minute at which the workpiece rotates (the Motor speed may differ). Most of our Lathes offer infinitely variable Speed control within a Speed range.

- The speed levels are usually regulated by manually shifting the drive belt to pulleys of different sizes. Many machines have two or more Speed ranges for small, light or large, heavy workpieces. Motor speeds from 150 to 2900 rpm, for example, are divided into different levels: 150-450, 400-1200 or 950-2900 rpm.

Low speeds are particularly important when turning large, unbalanced parts or when grinding. High speeds allow you to work quickly and achieve a better surface finish. Inexpensive Lathes also generally offer high speeds, but fail to achieve even revolutions at low speeds.

- Engine power is given in kilowatts (kW) or horsepower and refers to the power that the machine has. Engine power of 0.75 to 1.5 kW (1 to 2 hp) is common.

For larger diameters (e.g. for bowl turning), you need a lathe with at least 1.5 HP. It is perfectly possible to machine large Shawls on less motorised lathes with only 1 hp, but the lathe will sometimes stop or suffer a drop in speed with large cutting forces. And the fun factor suffers immensely!

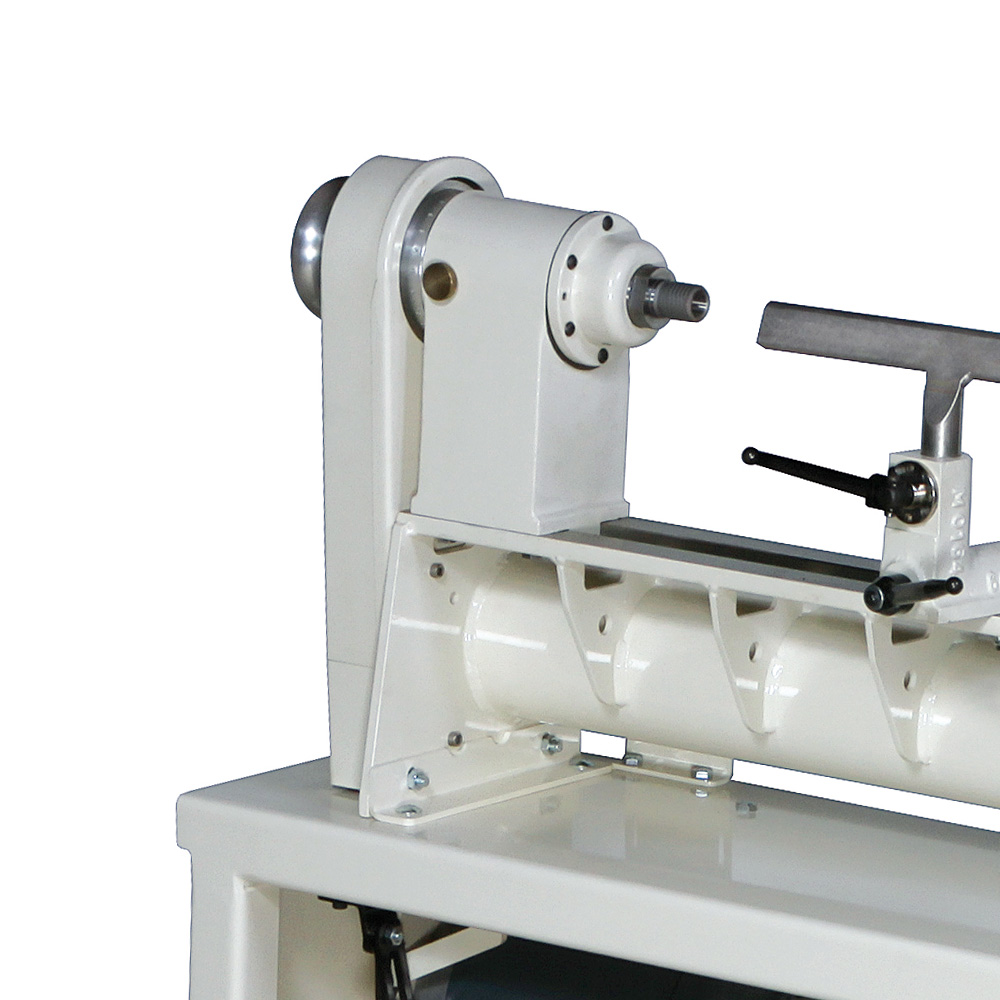

- The spindle thread is used to screw on clamping devices such as Chucks, Faceplates and other accessories. Threads with M33 x 3.5 or 1" x 8 tpi are common. Only accessories with an exactly matching internal thread will fit onto the respective external thread, i.e. only a chuck with an M33 adapter will fit onto an M33 thread and only a chuck with a 1" adapter will fit onto a 1" thread. The 1" thread (Diameter 25.4 mm) is weaker than the M33 thread (Diameter 33 mm), which is why it is only suitable for smaller chucks (e.g. Talon).

- The specification 4-fold or 3-fold bearing spindle indicates the number of bearings in the headstock. The logical consequence would be that a spindle with 4 bearings runs more smoothly than a spindle with 3 bearings. However, this is only partially correct, as it also depends on the type of bearing and the quality of the bearings installed.

- The Morse taper of the quill. The quill is the component that moves back and forth in the Tailstock and into which, for example, the travelling centre punch is inserted. MK2 or MK3 quills are commonly used. Here too, only accessories (centre point, Drill chucks etc.) with the same cone will fit.

Decisive equipment features of a Lathes:

- Infinitely variable speed control. Most lathes now have electronic speed control, which allows their speed to be infinitely adjusted within one speed level. High-quality frequency converters allow simple switching of the direction of rotation (e.g. necessary for external rotation) and a soft start for large workpieces. Only older or very simple models always require the drive belt to be reversed for Speed control.

- Hollow spindle. If the spindle of the Lathes is hollow, you can, for example, eject square drivers with a bar or drill out the workpiece through the spindle with a special Length drill (e.g. for lamp bases).

- Parts equipment. The spindle of the Lathes can be stopped and locked in a certain grid. This is useful, for example, if you want to apply evenly spaced decorations to the circular outside of a workpiece or drill holes for spokes in an axle with precision.

- High Weight. The Weight of the machine is a decisive factor for the smooth running of the machine. Generally speaking, the heavier the lathe, the better. However, not every craftsman has a machine shop available that is designed for heavy weights. For this reason, and also for reasons of easier transport, a middle ground usually has to be found. Some lathes can therefore be filled with sand after being set up.

Lathes from the various Manufacturers

DICTUM

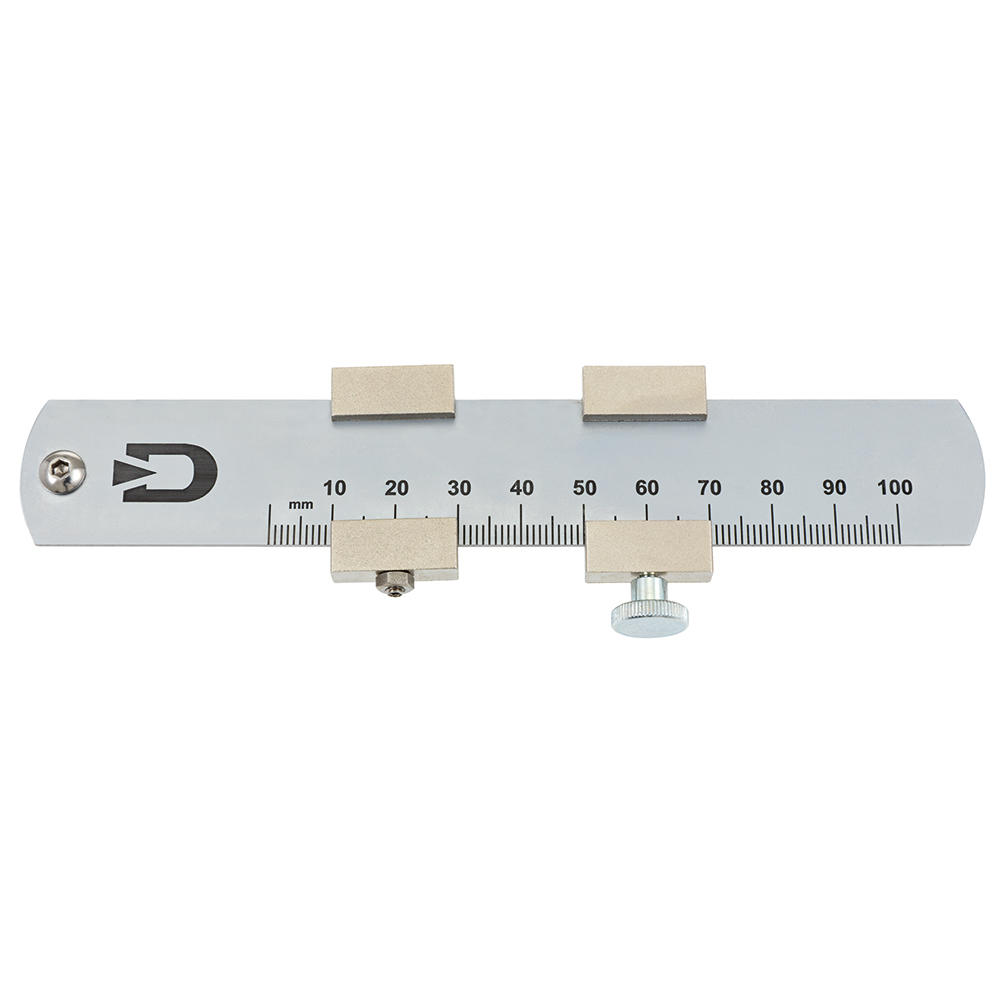

We offer a bench lathe that sets itself apart from the competition with numerous helpful gadgets. These include a Tailstock quill, which can be used to drill directly without a Drill chucks with MK2 Direct collet chucks. This makes it possible to use the full Distance between centres of the Lathes, e.g. when drilling out pepper mills. A depth setting gauge with depth limiter for drilling is also available for this purpose.

Axminster Professional Series

The Professional series offers lathes in the mid-price range with high performance and robust construction. With a recommended utilisation of around 1000 operating hours per year, they are ideally suited for use in the workshop of ambitious hobbyists. The high quality of workmanship, outstanding precision and stability of the machines impress many professionals. All machine parts are available from DICTUM as spare parts.

Oneway

The innovative design of the Oweway Lathes combines the positive properties of solid grey cast iron with the advantages of stable welded Steel constructions. These machines are equipped with the latest technology. Manufactured with high precision, these Canadian-made Lathes guarantee a long service life and the pleasure of woodturning. Each Oneway lathes is supplied with a faceplate.

HAGER

With more than 40 years of experience in the Production of Lathes, the Englisch company HAGER is now one of the leading Manufacturers worldwide. HAGER lathes are manufactured in accordance with DIN standards and the procurement of spare parts is guaranteed for the long term. Very practical: all accessories are compatible with all Lathes.