Understanding and correctly using glues and adhesives

Adhesives can be used to join different materials without changing their properties and structure. In addition to holding materials together, adhesives fulfil several tasks. Adhesives can bridge fitting tolerances and fill joints, equalise the different expansion coefficients of materials, seal, insulate and much more. The production of complex components, flat connections and lightweight construction (sandwich panels) are only possible with adhesives.

- What is adhesion and cohesion?

- Important time concepts in gluing

- Waterproof, water-resistant and the standards

- Which glues are natural?

- What are dispersion and PVAc glues?

- What are chemical adhesives and reaction adhesives?

- Hot melt adhesives

- Adhesive tapes

- Application methods

- Little helpers

- Checklist

This article is an extract from our online course Glues and adhesives in the wood workshop. It is aimed at anyone who would like to work with different adhesives in their own workshop.

What is adhesion and cohesion?

The mechanism of gluing and bonding is based on the interaction of two essential factors:

Adhesion refers to the force that makes one material stick to another (adhesive force).

Cohesion is the force that holds a material together and is also known as "internal strength".

Both sufficient adhesion and cohesion are necessary for a stable bond. For certain tasks, for example in instrument making, adhesives are deliberately used whose cohesion is lower than that of the workpieces, as a break in the glue joint is easier to repair here than, for example, the reconstruction of a soundboard . You can find more information on thisin our video. Types of stress and construction The core principle of adhesive construction is: "The stress must be less than the load-bearing capacity!"

Load types and design

The core principle of adhesive design is: "The stress must be less than the load-bearing capacity!"

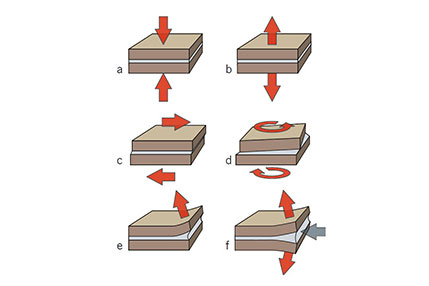

Every construction is exposed to certain forces (stresses) that put more or less strain on it. With the types of mechanical stress shown on the left (a. pressing, b. pulling, c. shearing, d. twisting, e. peeling and f. splitting), the stress on the bonded joint increases steadily from a. to f.. Adhesive joints can therefore generally withstand compressive and tensile loads very well, but most adhesive joints fail under the load of peeling or splitting forces.

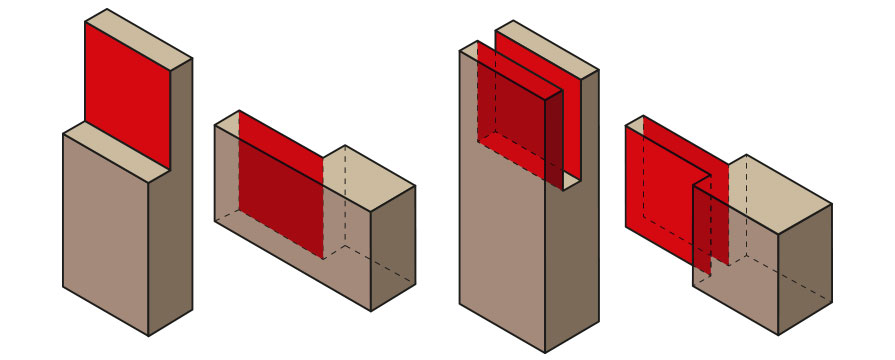

Even a single tenon increases the gluing area by twice as much as an overlap.

The optimum connection

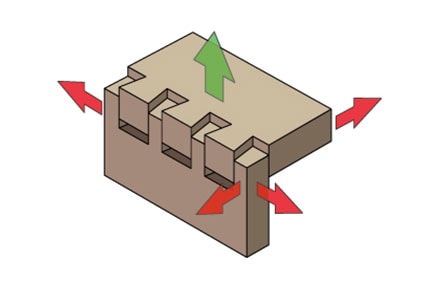

Most modern glues have a higher load-bearing capacity than wood as a material. Properly joined and professionally glued, even a butt-glued joint is more likely to break in the wood than in the glue. The aim of the design should therefore be to optimise the position and size of the glued surfaces (load-bearing capacity) in accordance with the expected mechanical loads. Classic timber joints are a prime example of good construction. On the one hand, they increase the surfaces to which the glue adheres. Even a simple mortise and tenon joint doubles the glued surfaces compared to an overlap. Secondly, the shape of many timber joints transfers the stresses that occur into the solid components. For example, a form-fit joint with dovetail tenons can withstand tension and compression in several axes even without glue. The prerequisite for a durable glued joint is therefore always a professional design.

This corner joint with dovetail tines cannot be displaced in two axes due to the positive fit.

Important time concepts in gluing

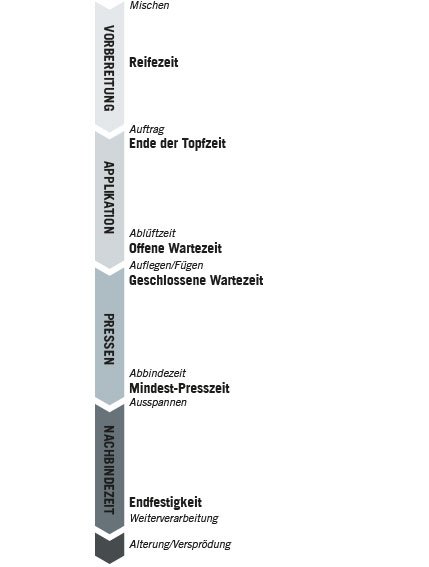

Adhesives (pastes) that are mixed or stirred to swell or achieve a homogeneous structure before they can be processed requirea maturing time.

Pot life indicates how long a 2-component adhesive can be processed after mixing.

Flash-off time is the minimum time during which the (contact) adhesive should outgas before the parts to be joined can be brought into contact with each other.

Open (waiting) time is the maximum time between application of the adhesive and bringing the parts to be joined together.

Closed (waiting) time is the maximum time between bringing the parts to be joined together and pressing.

Setting time is the time required for an adhesive to achieve so-called hand strength. As a rule, it is at least equal to the pressing time.

Theminimum pressing time is reached when the clamps can be released or the workpiece can be moved again without load.

Final strength is achieved when curing is complete and the adhesive has reached its maximum strength.

Waterproof, water-resistant and the standards

Glues are divided into different stress groups, which classify them according to their behaviour when exposed to moisture and water. In Germany and the EU, adhesives are divided into four stress groups according to EN 204:

- D1: These glues have the lowest water resistance and are only suitable for indoor use.

- D2: Glues in this group are suitable for indoor use with occasional short-term exposure to water and condensation.

- D3: D3 glues are intended for indoor use with frequent short-term exposure to water. They are also suitable for outdoor use without direct exposure to weathering.

- D4: The addition of hardener turns D3 glues into D4 glues, which are considered boiling water resistant and are used indoors with frequent long-term exposure to run-off water. For outdoor use and weathering, they also require appropriate surface protection.

The European standard EN 204 relates to timber constructions such as those used in window construction or load-bearing timber construction. In contrast, the US standard ANSI/HPVA, which is specified for Titebond adhesives, for example, refers to plywood production. Accordingly, the terms used are different.

- ANSI Type I: Waterproof Suitable for outdoor use. The glue joint withstands constant exposure to moisture (rain). Not suitable for use under water.

- ANSI Type II: Water-resistant Suitable for outdoor use. The glue joint can withstand occasional exposure to moisture (rain) as long as it is not permanently wet.

- ANSI Type I therefore corresponds approximately to groups D3-D4, ANSI Type II approximately to D2-D3. The term "waterproof" is interpreted differently in the two standards. In the ANSI/HPVA standard, waterproof means "withstands constant exposure to moisture (rain)", while in EN 204 it means "frequent short-term exposure to water or high humidity".

In our video tutorial, we compare Titebond® glues in terms of times, water resistance and applications!

Which glues are natural?

Bone glue:Bone glue(No. 450141) is particularly suitable for hard joints, it is easy to sand dry, resistant to ageing and easy to repair.

Hide glue:These glues(No. 450140) are used for all joints that remain flexible, e.g. for book spines or in instrument making. Hide glue is made from animal skins.

Hare glue:This glue(No. 450153) is very economical, has a higher viscosity and can be applied thinly. It is more elastic than hide and bone glue and is used in musical instrument making and veneering.

Isinglass glue:This glue(No. 450142) has a considerably higher strength than other animal glues. The concentration of glue in the solution can therefore be much lower than with bone or hide glue, for example. The yield of isinglass glue granules is correspondingly high. The granules offered by DICTUM come from untreated swim bladders of a Russian sturgeon species (Hausen). The catch quotas are strictly regulated so as not to jeopardise the population of this rare fish species.

Fish glue:This glue(No. 450188) combines the good properties of bone glue and hide glue. It is characterised by its high strength and yet remains very flexible. Fish glue is used in furniture making. One advantage is its cold application. For repairs, it can be loosened again by heating.

Tip:To prevent unused glue residue from becoming mouldy, we recommend using citric acid, available from pharmacies and drugstores. Just a few drops in the glue are enough to prevent moulding.

| Glue | Art. No. | Materials | ||

| Wood + wood | Wood + paper | Wood + leather | ||

| Bone glue, granulate | 450141 | ●● | ● | |

| Bunny glue, granulate | 450153 | ●● | ● | ● |

| Hide glue, granules | 450140 | ●● | ● | ● |

| Isinglass glue, granules | 450142 | ●● | ●● | ● |

| Fish glue (ready to use) | 450188 | ●● | ● | ● |

Requirements (applies to all animal glues) |

|||

Waterresistant | Permanently waterproof | Temperatureresistant | Detachableagain |

| - | - | - | ++ |

| - | - | - | ++ |

| - | - | - | ++ |

| - | - | - | ++ |

| - | - | - | ++ |

What are dispersion and PVAc glues?

In dispersion adhesives, the binders are very finely dispersed in water.

Dispersion adhesives are often based on polyvinyl acetate (PVAc), which is why they are usually referred to as PVAc white glues. One exception among the glues listed here is Titebond Original, which is an aliphatic dispersion resin adhesive.

Advantages: Free of toxins and solvents, ready to use, easy to apply, can be dissolved by heat if necessary (thermoplastic), good shelf life.

Disadvantages: limited resilience.

Titebond® glues

The first choice when strength counts: for high-strength glued joints in woodworking, restoration and musical instrument making. For over 65 years, Titebond from the USA has been the market leader for professional wood adhesives.

Titebond® Original, II or III?

In brief, Titebond Original, II and III adhesives differ in their so-called open time and their resistance to moisture. Titebond Original glue corresponds to a normal PVAc white glue. Titebond II Glue Premium has the same open time as Titebond Original, but is waterproof with ANSI Type 2. Titebond III Glue Ultimate has a relatively long open time, is water-resistant with ANSI Type 1 and can also be processed at low temperatures.

Titebond® Glue Original

This glue(No. 450360) is suitable for all high-strength adhesive bonds of wood, laminate, fibreboard, leather, horn, bone, mother-of-pearl, fabric and porous materials in interior areas.

Titebond® II Glue Premium

For waterproof bonds with occasional exposure to moisture indoors and outdoors(no. 450364).

Titebond® II Glue Extend

The main advantage of this glue(No. 450387) is its long open time. It is particularly suitable for long bonding times for complex and large components in interior and exterior areas.

Titebond® III Ultimate glue

Highest strength, high initial bonding force and a long open time of at least 10 minutes make it the preferred glue(no. 450362) for high demands in interior and exterior areas.

Titebond® II Glue Dark

Brown tinted glue (No. 450372) for waterproof joints with occasional exposure to moisture indoors and outdoors (exterior doors, garden furniture, etc.). Especially for inconspicuous glue joints in dark woods such as teak or iroko.

Titebond® transparent glue

Ideal glue (No. 450396) for universal use in the household and in furniture construction with transparent curing glue joint and short pressing time.

Titebond® veneer glue

High-quality veneer glue(No. 450385) for cold pressing work in conjunction with open-pored materials such as wood and wood-based materials.

Titebond® moulding/modelling glue

This viscous glue (No. 450388) does not drip and is therefore ideal for vertical glue joints and overhead applications such as cornice fixings, window reveals and ceiling mouldings.

Bindan® glues

For over 80 years, the German company Bindulin has specialised in the production of glues and adhesives. With 20 different wood glues under the Bindan brand alone, Bindulin offers an exceptionally wide range of products for many applications.

Bindan-BB® wood glue

Pollutant-free glue(no. 450526, 100g) for sensitive areas such as bedrooms, children's rooms, nurseries, etc. It has good binding properties and is suitable for waterproof bonding of softwoods and chipboard, as well as for handicrafts.

Bindan®-Blitz

Wood and assembly glue This glue(no. 450531) builds up strength particularly quickly and is therefore perfect for assembly work. It has outstanding bonding strength and is suitable for waterproof gluing of wood, chipboard and fibreboard. It is also suitable for high loads on the workpiece, such as windows and doors. Ideally suited as a finished parquet glue (tongue and groove gluing).

Bindan-IQ® wood glue

The ideal wood glue (No. 450530, 280g) for waterproof gluing of light-coloured or tannin-rich woods that are prone to discolouration. Normal white glue has an acidic pH value - this can cause stains and discolouration in combination with tannic acids and other wood ingredients. IQ wood glue is PH-neutral and therefore prevents discolouration of woods such as maple, Douglas fir, chestnut, larch, lime, walnut, etc. (for oak containing iron). (not suitable for oak containing iron).

Bindan-P® "Propeller Glue" Wood Glue

High-quality, ready-to-use glue(no. 450528, 100g) with outstanding bonding strength for waterproof joints in windows and exterior doors as well as future high loads on the workpiece. For wood, wood-based materials, cardboard, polystyrene, felt, fabric and leather.

| Adhesive | Art. No. | Materials | ||

| Wood + wood | Wood + paper | Wood + leather | ||

| Titebond® | ||||

| Glue Original | 450360 | ●● | ● | ● |

| II Premium glue | 450364 | ●●● | ● | ● |

| II Glue Extend | 450387 | ●●● | ● | ● |

| III Glue Ultimate | 450362 | ●●● | ●● | ● |

| Transparent glue | 450396 | ●● | ● | ● |

| Hide glue | 450368 | ●● | ● | ● |

| Moulding/modelling glue | 450388 | ●● | ● | |

| II Dark glue | 450372 | ●● | ● | ● |

| Veneer glue | 450385 | ●● | ● | ● |

| Bindan-BB® wood glue | 450526 / 450527 | ●●● | ● | ● |

| Bindan®-Blitz wood and assembly glue | 450531 | ●●● | ● | ● |

| Bindan-IQ® wood glue | 450530 | ●●● | ● | ● |

| Bindan-P® propeller glue Wood glue | 450383 / 450529 / 450528 | ●●● | ● | ● |

Requirements for |

|||

Waterresistant | Permanently waterproof | Temperatureresistant | Detachableagain |

| - | - | - | + |

| + | - | ||

| + | - | ||

| + | + | ||

| - | - | + | |

| - | - | ++ | |

| + | - | - | + |

| - | - | - | + |

| + | + | -/+ | - |

| + | + | -/+ | - |

| + | + | -/+ | - |

| + | + | -/+ | - |

What are chemical adhesives and reactive adhesives?

Reaction adhesives

Solvent-free adhesives with 100 % solids content. They are liquid or paste-like when applied and achieve their final strength through a chemical reaction in which at least two reaction partners are involved.

With one-component adhes ives (PUR adhesives, instant adhesives), the reaction takes place by means of an initiator (e.g. air humidity, accelerator).

Two-component adhes ives (epoxy resin adhesives) harden by mixing two reactive substances (resin and hardener).

Advantages: high load-bearing capacity, adaptation to application methods through formulation.

Disadvantages: hazardous to health, difficult to apply/mix.

Gap-filling or gap-bridging

PU adhesives foam up during processing and thus have a "gap-filling" effect. However, the foamed and cured adhesive itself has a lower strength than a thin, non-foamed adhesive layer. It does not transfer loads from one component to the other. If larger gaps (> 0.5 mm) are to be bridged, a "gap-bridging" adhesive is required. These include, for example, epoxy resins and construction adhesives, but also some PVAc white glues.

Titebond® PU adhesive

Highly resilient, waterproof construction adhesive for universal use. In addition to wood-wood joints, also suitable for almost all porous or solid material combinations (metals, ceramics, plastics, stone, etc.).

The advantages: high final hardness, cavity-filling, short pressing time, excellent sandability, can be painted over, non-toxic and solvent-free.

Materials |

|||

Wood + wood |

Wood + metal |

Wood + paper |

Wood + plastic |

| ●● | ● | ● | ● |

Wood + stone |

Wood + leather |

Plastic + plastic |

Plastic + leather |

| ● | ● | ● | ● |

Requirements for |

|||

Water resistant |

Permanently waterproof |

Temperature resistant |

Detachable again |

| + | ++ | - | - |

Titebond® instant adhesive for wood

Fast adhesive (no. 450375 - several viscosities available!) for small contact surfaces with a narrow joint gap, especially for bonding wood and wood-based materials. However, other materials such as natural rubber, aluminium, stainless steel, fibreglass, PVC and porcelain can also be bonded to wood and wood-based materials as well as to each other without any problems. The individual types differ in viscosity and hardening speed. Advantages: solvent-resistant, ideal for bonding mitre joints made of MDF and porous woods, high ageing resistance and can be painted over.

Materials |

|||

Wood + wood |

Wood + metal |

Wood + paper |

Wood + plastic |

| ● | ● | ● | ● |

Wood + stone |

Wood + leather |

Plastic + plastic |

Plastic + leather |

| ● | ● | ● | ● |

Requirements for |

|||

Water resistant |

Permanently waterproof |

Temperature resistant |

Detachable again |

| + | + | - | - |

Activator for instant adhesives

The activator*(No. 451981) accelerates the curing of instant adhesives (cyanoacrylate adhesives). It is used for highly absorbent and porous surfaces, low humidity and temperature or thick layers of adhesive. Can be used in combination with Titebond superglue for wood.

Bindulin Duo-Col® two-component adhesive

Slow-setting epoxy resin adhesive(No. 450382) for the chemical "welding" of metals, steel, plastics, hard materials, also for bonding glass, porcelain, concrete and wood. Resistant to water and chemicals. Temperature resistant from -20 to max +70 °C, pale yellow adhesive joint.

Ber-Fix® epoxy adhesive

Bonds almost anything: fast-setting epoxy resin adhesive(no. 450417 and no. 450379). Bonds metal, wood, glass, hard plastics, porcelain, ivory and precious stones, among others. Resistant to water and chemicals. Double syringe with attachable mixing nozzle, transparent glue line.

Materials |

|||

Wood + wood |

Wood + metal |

Wood + paper |

Wood + plastic |

| ● | ● | ● | ● |

| ● | ● | ● | ● |

Wood + stone |

Wood + leather |

Plastic + plastic |

Plastic + leather |

| ● | ● | ● | ● |

| ● | ● | ● | ● |

Requirements for |

|||

Water resistant |

Permanently waterproof |

Temperature resistant |

Detachable again |

| + | ++ | + | - |

| + | ++ | ++ | - |

Solvent-based contact adhesives

The adhesive substances are dissolved in the solvents. The transition from the processing state to the solid final state takes place by diffusion of the solvents.

Contact adhesives are so called because two adhesive films are brought into contact with each other and bond immediately when pressed (Velcro principle).

Advantages: short pressing time, immediate load-bearing capacity, elasticity, moist substrates can be bonded.

Disadvantages: Health hazard, limited resilience.

Kövulfix pressure sensitive adhesive

Professional solvent-based contact adhesive(no. 451980) for use in the leather sector. The adhesive achieves full adhesion after being pressed on once. It is also suitable for rubber (soles, seals), rainwear, hard PVC and soft foam (polyurethane foam, carpet backing), paper, cardboard, textiles, felt, cork and wood.

Materials |

|||

Wood + wood |

Wood + metal |

Wood + paper |

Wood + plastic |

| ● | ● | ● | ● |

Wood + stone |

Wood + leather |

Plastic + plastic |

Plastic + leather |

| ● | ● | ● | ● |

Requirements for |

|||

Water resistant |

Permanently waterproof |

Temperature resistant |

Detachable again |

| + | + | - | - |

Tip:With contact adhesives such as Kövulfix, the so-called initial pressure is decisive for the strength of the bond. In the professional sector, this pressure is achieved by pressing hard. For domestic use, this is achieved by a single strong blow with a hammer. Allow the Kövulfix adhesive to flash off as described in the instructions, place the parts to be joined on top of each other and then tap them firmly with one or more hammer blows. Of course, this only works when bonding hard-wearing materials such as leather and rubber to wood or metal. Make sure the hammer is clean!

Which hot melt adhesives are available?

STEINEL® Neo2 cordless hot-melt glue gun

Everything under control. Without a cable, but with plenty of gluing power. Cordless hot glue gun neo2 (No. 720483) - Professional quality in a handy format: the cordless hot glue gun neo2 is the ideal partner for all DIY enthusiasts. The cordless power pack with powerful rechargeable battery is ready to use in 15 seconds and works continuously for up to 30 minutes. It joins almost all materials cleanly and precisely - whether metal, wood, plastics, ceramics or much more.

STEINEL® Neo1 rechargeable hot glue stick

Small, fast, drip-free. The new hot glue generation (no. 720482) takes care of craft, decorative and small repair jobs with the neo1. Mobile, fast, precise - and completely drip-free, because the innovative mechanism absorbs the adhesive immediately after use. Even children can glue safely thanks to the non-toxic accessory sticks, because the device switches off automatically when not in use. After 15 seconds, the neo1 is ready to go again and, thanks to its modern lithium-ion battery, lasts for around 200 applications. It has to. After all, it is now in continuous use.

STEINEL® Gluematic 5000 hot glue gun

Powerful. Clean. Flexible. Without compromise. Fixing wooden dowels, gluing picture frames or attaching flower arrangements: No problem for the powerful Gluematic 5000 (no. 720489) - anywhere and at any time. After just three to five minutes of warm-up time, the tool is ideally suited for 20 minutes of cordless work thanks to modern heat storage. The all-rounder with a very high melting capacity (22 g/min) can of course also be connected directly to the power supply for large-scale and longer gluing jobs.

Tip:When gluing curved or bent workpieces, it is often difficult to apply clamps in such a way that they apply sufficient pressure to the glue joint. Temporary clamping blocks can provide a remedy. To prevent the clamps from slipping, fix wooden blocks in a suitable place with hot glue. Once the glue has set, you can remove the blocks by carefully heating them with a hot air gun.

You can find more information about choosing the right adhesive in our overview table.

Adhesive tapes

Easy to handle, flexible and versatile. Adhesive tapes have one major advantage: they are ready for immediate use.

Washi tape

Very thin and wet-strength adhesive tape(no. 820274 / 820275) made from Japanese Washi paper with specially adjusted acrylate adhesive formulations that moulds perfectly to contours.

- High UV stability

- Adhesive strength matched to the substrate

- Developed for all indoor and outdoor work with paints and varnishes

- Produces very flat and sharp coloured edges, virtually no underflow of paint/varnish/finishing.

Joint glue paper

Well-adhering white joint paper that can be sanded off without leaving any residue after veneering.

- Perforated(no. 450138): The tops of the joints can be checked thanks to the triple perforation and sanding is much easier.

- Unperforated(no. 450139): The unperforated surface means that even small tears have good adhesion, making the joint gluing paper ideal for inlay and marquetry work.

Application process

It is very easy to make mistakes when mixing and applying adhesives, which can have a negative impact on the strength and durability of the bonded joint. Great care must therefore be taken during these work steps.

The correct mixing ratio

In addition to the actual application of two-component adhesives, mixing the components is also part of the application process. Particular attention is required here, as deviations in the mixing ratios can lead to a reduction in strength or even total failure of the adhesive. An increased addition of hardener does not usually result in the adhesive setting faster or becoming stronger - on the contrary, the hardener components do not find any reaction partners and remain unbound in the mixture.

Glue bead

The viscosities of PVAc wood glues are adjusted so that they can be processed using different application methods. It is important that the glue is applied evenly. When simply applying the glue from the bottle, it is advantageous to apply the glue in bead form (left) and not in closed curls (right), as otherwise air pockets and thus unglued areas may occur during pressing.

A zigzag-shaped glue bead (left) ensures an even and closed glue joint without air pockets compared to a random glue application (right).

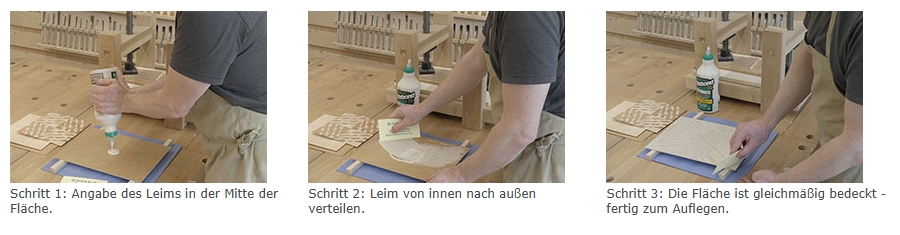

Flat glue application

Professional glue rollers are an excellent, but expensive tool for applying glue to large surfaces, as is common in veneering. An inexpensive alternative is to apply glue using a notched trowel (e.g. Bindan glue trowel, no. 800499).

A limited amount of glue is poured into the centre of the surface and spread with the notched trowel. It is important to always work quickly from the centre outwards. The excess glue will then adhere to the edges and the edges will remain clean.

Wash the glue spatula well under running water immediately after application or simply remove the dried glue residue from the spatula later.

We explain more about this for you in our video tutorial!

Tip: Gluing without clamps? Wood glues do not require pressure during gluing to set - they also harden without pressure. The pressure is needed to improve the joint fit and penetration behaviour. Small parts such as spacer blocks or concealed feet can also be glued on simply by rubbing. When both joint surfaces are clean and even, apply a little glue to the block and press it on, moving it slightly back and forth, until it is firmly seated in the correct position. This method is only suitable for components that cannot be seen, as the glue will smear the surrounding surface.

Little helpers

- GluBotTM glue dispenser(no. 716004)

- Glue spray bottle(No. 800496)

- Glue brush with natural bristles in different versions (No. 706192)

- Glue syringes with flexible attachment (No. 706169)

- Bindan glue spatula(No. 800499)

- DICTUM spheroidal graphite cast iron screw clamp enables high force transmission while remaining rigid and unyielding.(No. 720423)

- DUBUQUE aluminium joint clamp is ideal for fast and comfortable work.(No. 707690)

- Pony band clamp as an ideal clamping aid for picture frames, shelves, furniture and other workpieces.(No. 708908)

- Kunz glue scraper/tree scraper for scraping off dry glue residues and scraping off paint residues.(No. 703161)

Checklist

What should you pay attention to when gluing?

Planning

Think about the order in which the parts are to be assembled. Mark the workpieces so that their position in the finished furniture is clearly recognisable. Are sufficient aids such as clamps and shims available? Or would it be better to glue in several steps? In the daily plan, the ideal time for gluing is shortly before the end of the working day. The glued joints can then harden overnight and work can continue the next day.

Preparation

Create space to work! Clear away any tools you don't need. A workpiece can quickly be scratched by a hammer lying around. Have a sufficient number of all tools such as glue bottles/brushes, fixtures, mouldings and clamping tools ready. Check all workpieces again: Have all holes been drilled? Have all inner surfaces been sanded? Do you know where each part belongs? If in doubt, try assembling the parts without applying glue.

Execution

Keep windows and doors closed, draughts can cause a film to form on the gluing surface. Mouldings create distance to the workbench surface, dripping glue contaminates the workpiece less, clamps can be applied and positioned more easily. Supports distribute the pressure evenly and prevent pressure marks. For larger workpieces, ask a helper to hold the parts. Initially only tighten the clamps with moderate pressure. Only increase the pressure when all clamps are correctly seated. Work quickly and rapidly, but without rushing. Observe the specified times (pot life, open time, pressing time, etc.).

Checking & corrections

Check all joints for open gaps and increase the clamping pressure of the clamps if necessary. If a gap does not close despite high pressure (and hammer blows), the cause may be incorrect dimensions (e.g. tenon too long) or contamination. Then action must be taken quickly! Quickly dismantle the affected parts and immediately remove the glue, find the cause and rectify it. Check that the workpiece is at a right angle. The two diagonals in the carcass/frame are compared using the so-called gauge (you can find a tutorial on the gauge here).

After gluing

Do not immediately remove any glue that has oozed out with a cloth or scraper. There is a risk of glue spreading over the surface. It is better to allow the glue to set a little and then carefully cut it away with a knife or chisel. You can mask sensitive surfaces with adhesive tape before gluing. Observe the pressing time. The clamps should only be removed once this has elapsed. Pressure marks from clamps can usually be "ironed out" again using moisture and heat.

THE MOST IMPORTANT STEPS AT A GLANCE

- Clearly mark the workpieces (e.g. with a carpenter's triangle)

- Prepare the required tools

- Plan the assembly process, try it out without glue if necessary

- Close windows and doors

- Use of mouldings and supports

- Helpers to hold larger workpieces

- Initially only tighten clamps with moderate pressure

- Observe the specified times (open/closed waiting time)

- Check connections for open gaps/contamination

- Is the workpiece at a right angle?

- Compare the diagonals in the carcass/frame using a jig gauge

- Allow swollen glue to set and cut off

- Do not remove the clamps until the pressing time has elapsed

Unsere Top Auswahl für Sie

You can find detailed information on glues and adhesives and their possible applications in our adhesives guide.

For more interesting facts about glues and materials, we offer an online course on this topic: Glues and adhesives in the wood workshop.