Axes and hatchets

-

Woodworking / metalworking

- Saws

- Chisels

- Carving tools

- Axes and hatchets

- Hammers, nails & pry bars

- Planes

- Woodturning tools & lathes

- Rasps & files

- Measuring and inspection tools

- Scribing & cutting tools

- Routing & drilling tools

- Clamps

- Screwdriving tools

- Pliers

- Workshop equipment & tool sets

- Blacksmithing / blade finishing

- Engraving tools

- Leatherworking, papercraft & upholstery tools

- Stone working tools

- Tools for kids

Axes and hatchets

EXPERT KNOWLEDGE AXES AND HATCHETS

Differences in the terms axe and hatchet:

In contrast to hatchets, axes have a heavier head (0.8 to 2.5 kg) and a longer handle (Length 550 to 700 mm), on which they are wielded with both hands. Hatchets have a weight of 0.6 to 0.8 kg and can be wielded with one hand on the handle (approx. 500 mm). For regional reasons, however, both terms are also used for the same tools.

What types of axes and hatchets are there?

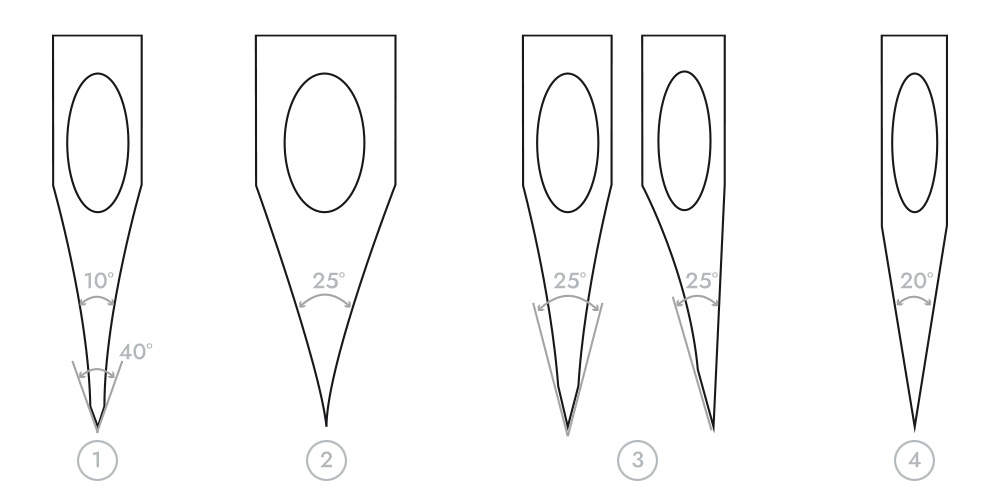

- Cutting and splitting

The cutting edge of a forestry axe or felling axe has a sharp wedge angle for cutting the wood fibres; some also have a blunter cutting edge angle (secondary bevel) to increase the service life. - Splitting

To maximise the splitting effect, the cutting edge of a splitting axe or cleaver has a blunt angle, while the usually straight handles increase accuracy. The high weight of the axe head supports the force exerted when splitting wood. - Fitting and hewing axes

A traditional hewing axe has a one-sided bevel with a medium wedge angle for fitting and hewing beams. Large, flat axe blades, wide bevels with a straight edge and offset handles ensure a large contact surface. - Garden axes

Garden axes predominantly have a heavy or flexible axe head and a thin, sharp blade that absorbs the load during springy strikes (e.g. against wild growth or thin branches).

How do I find the right axe?

Firstly, answer the following question: What do you need the axe for? If you want to split logs, you need a splitting axe or a splitting hammer. A splitting axe has a heavy head and a straight axe handle made from hickory or ash. If you want to continue splitting finished firewood to make kindling, a light splitting axe is sufficient. A felling or forestry axe with a lighter head and a curved axe handle is used for felling and limbing trees to make it easier to hit them from the side. A universal axe or a trekking axe with a low overall weight is practical for outdoor activities and bushcraft. An axe that you use for sculpting work should be light, have a short handle and a downward-pointing blade (so-called beard) so that you can use it to carve out details with precision. In our shops, you can try out, test and compare all axes from DICTUM, Hultafors, Gränsfors and other Manufacturers before you buy.

What steel is used to forge axes?

Most forges use steels such as C45, C55 and S55C (carbon steel), which combine high strength and low wear with toughness. The number in the steel designation indicates the carbon content (e.g. C45 has 0.45 % carbon content). A higher carbon content enables a higher final hardness of the blade. Approx. 54 HRC can be achieved with C45 Steel and approx. 60 HRC with C60 Steel. However, the forging process and the degree of forming that takes place also have a major influence.

Whether hand-forged or industrially manufactured, steel, and therefore the axe, always loses carbon when heated. If an axe or hatchet is produced in several forging passes, the carbon content decreases and with it the achievable hardness. Steel with a low carbon content can therefore be used for simple drop forging work. For open-die forging work with complex head shapes, the proportion must be significantly higher. However, a higher degree of forming also has some advantages. The steel structure is compacted further with each forging pass and the axe becomes stronger. If, for example, C55 is only heated once for an axe and then industrially "forged" in large presses, the head will have the same hardness as an axe head made of C60 Steel, but its strength will not be the same. The forming process increases the strength of the blade and enables a fine-grained, break-resistant cutting edge. In the final process, the axe head is heated again and then hardened by rapid cooling.

How can I sharpen axes and hatchets?

As axes are often used outside the workshop, a mobile sharpening device, such as a diamond flap sharpener or a combined roughing and sharpening stone, is recommended. These have two different grits for pre-sharpening and sharpening. To sharpen, place the axe head on a solid base, e.g. a tree stump, and guide the sharpener across the cutting edge with even movements. Always maintain the cutting edge angle. Once one side has been sharpened and a continuous burr has formed, turn the axe over and repeat the process. You will find everything you need for sharpening tools in our "Sharpening " category.

How do I care for axes and hatchets?

Do not leave axes and hatchets lying on the ground in damp meadows or forests. Protect the sharp cutting edge during transport with a Leather sheath or a robust Leather blade guard. Clean your axe after work with water and a brush or cloth and then dry everything thoroughly. Resin residues can be easily removed with resin solvent. Finally, we recommend applying some oil (e.g. Ballistol Universal Oil) to the axe head to protect it from rust and reduce the build-up of resin and plant sap. If the handle wobbles, check the wedging and repair it. We stock the right replacement handle for almost all of our axes, so you can replace and re-shaft a broken axe handle. Our single-handle service staff will be happy to do this for you.