Adze

Content

Expert knowledge - Adze

The adze is a relatively unknown tool, yet unique in its function and extremely versatile. Success or failure in using the tool depends very much on its design. A good adze allows precise application and ergonomic use. A cheap model is often a bad investment because mass production does not set great store by ergonomics and functionality. Because the tool is not widely known, users are often unaware of the great differences in its use.

Pic 1

Pic 1 Pic 2

Pic 2 Pic 3

Pic 3 Pic 4

Pic 4 Pic 5

Pic 5There are 3 main criteria for optimum use of an adze:

- The correct stroke

- Using the blade

- Type of bevel

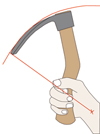

The adze is swung with the wrist, so this is also the pivot point of the tool. If you draw an arc around the centre of the wrist (marked by an x in the drawings) which runs along the top of the blade, this shows the curve in which the adze is swung (see figure 1 and 4).

The back of the adze that touches this curve is the support surface, similar to a plane. Figure 5 shows how an adze works that does not follow this radius, i.e. does not have a round back. This kind of adze cannot bite through wrist movement alone.

It must also be dragged (as when hoeing beds), which does not allow precise strokes and is not ergonomic. In addition, the adze is immediately driven out of the workpiece again because the elevation on the back acts as a kind of lever.

Figure 3 shows a trough-maker's adze that was made following this principle and works perfectly.

In the drawings, the radius is shown as a red line. Being the radius, this line is almost perpendicular to the back of the adze. So the full surface of the cutting edge meets the workpiece, similar to a plane blade.

In figures 2 and 5, the cutting edge does not fully align with this line. The adze in figure 2 thus penetrates the workpiece first with the sides of the curved blade. This makes it almost impossible to apply the adze with precision because you cannot work out when the tip will touch the workpiece. In figure 3, on the other hand, the tip of the adze touches the workpiece first, which makes it hard to apply the sides precisely.

-

Outside bevel:

This type of bevel changes the geometry of the adze. Figure 3 shows an exaggerated version of this. Similar to this bent back, the outside bevel also changes the angle of the support surface. Material can only be removed with additional hoeing movements (see above). An advantage of this version is that the blade cannot penetrate the workpiece too easily because the back quickly drives it back out. This bevel type is particularly suitable for rough removal of material. It is also easy to sharpen, similar to an axe.

-

Inside bevel:

The more elaborate inside bevel allows precise application of the adze and, if the back is swung correctly, ergonomic use from the wrist. An inside bevel is a must whenever you require highly precise strokes, e.g. in sculpting.

-

Combined inside and outside bevel:

If the outside bevel is slightly changed by using a very flat bevel, this allows a combination that offers all the advantages of both bevel types: inside bevel for precise application, outside bevel to prevent the adze from catching in the workpiece.

All the adzes marked with our  are designed according to the criteria detailed above. The heads are made by experienced master blacksmiths and are fitted by hand by a wainwright or our own sculpting course instructors. A variety of High Quality Adzes can be found in our Online Shop.

are designed according to the criteria detailed above. The heads are made by experienced master blacksmiths and are fitted by hand by a wainwright or our own sculpting course instructors. A variety of High Quality Adzes can be found in our Online Shop.