Router planes are perfect for finishing grooves and tenons. However, traditional wooden router planes and small metal ones lack the precise adjustment options found on the larger Veritas and Lie-Nielsen router planes. We'll let you in on a trick that you can use to set the depth precisely on almost any router plane.

Requirements

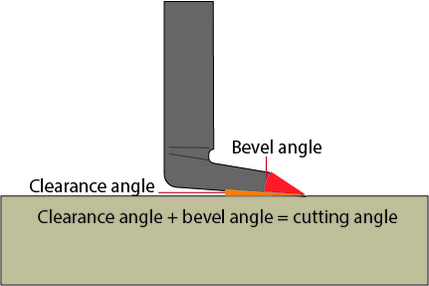

For our trick to work, the blade of your router plane must have a »clearance angle«, i.e. the blade must run upwards at a slight angle after the cutting edge. Basically, all industrially manufactured router plane blades have this bevel. Sometimes the clearance angle is missing on homemade or handmade plane blades.

The clearance angle ensures that the plane blade rests on the cutting edge only

Make the most of the clearance angle

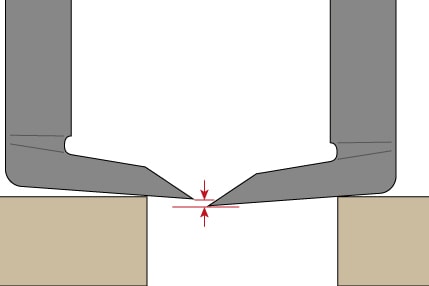

This slope on the router plane blade will help us to adjust the chip thickness. Place the router plane with the cutting edge of the plane blade on the edge of the workpiece. Loosen the locking screw of the blade. Now you can adjust the chip thickness by letting the cutting edge of the plane blade protrude over the edge.

To achieve a fine chip, let the cutting edge of the plane blade protrude only a few millimetres over the edge of the workpiece, press the blade down onto the workpiece and secure the locking screw again. If you want to remove more material, push the cutting edge further out.

The further the blade protrudes, the more material is removed when planing

Depth adjustment is performed in the same way. Place the router plane with the cutting edge at the edge of the machined surface (e.g. base of the groove) and let the blade protrude by the same amount as the desired chip thickness.

Tips on how to work with router planes

- Smooth surface

Roughly chisel out larger grooves in advance. Leave 2 to 3 mm still to remove at the bottom of the groove, then grab your router plane. For the first few layers, you can still take off slightly thicker chips. The closer you get to the bottom, the finer you set the chip removal. - Finish tenons

With a router plane you can rework tenons very precisely and adjust them to the thickness of the mortise. With mortise and tenon joints, the edges of the tenon are visible. Therefore, always plane from the outside inwards to avoid chipping at the edge. - Half-blind dovetails

A router plane is also very suitable for finishing half-blind dovetails. With a narrow or pointed router plane blade, you can »chisel out« the tenons right into the corners and down to the very base. - How to enlarge the support surface

For wide openings (e.g. overleap joints), you can place a piece of wood with the same thickness as the workpiece next to, in front of or behind the opening so that the router plane always has a stable support and does not tip over. - Pull stroke planing cuts

A router plane cuts more easily and cleanly if you plane »on the pull stroke«. To do this, the router plane is held by one handle while it is pushed or pulled into the material by the other. The movement is somewhat arc-shaped, thus the cutting edge cuts the wood at a slight angle. By alternately pulling or pushing, you can quickly work out recesses.