Wooden planes, which is already given by the name, are made of wood. Wood wears out and wood works. That is why a few things must be checked regularly and may need to be corrected when using wooden planes. This applies to all wooden planes! Have you got an old plane from a friend or bought one at a flea market? We will show you how to make the "old sweetheart" work.

Visual inspection

If you have purchased an old plane or have not used your plane for a long time, you should focus your attention on a few areas. Look at the plane from all sides. How is the sole of the plane, are there any signs of use? Hold a straightedge lengthwise and crosswise over the sole to see how straight the surface is. What does the blade of the iron look like? Is it rusted? Is there anything stuck in the mouth of the plane? Is the wedge intact, or does it have chipped edges? All of this allows you to draw conclusions about how the tool has been cared for and if there are any problems that need to be fixed.

The plane sole is checked for evenness with a straightedge

Sometimes the mouth of a plane is clogged with shavings. There can be different reasons for this. Maybe something is wrong with the lever cap. It may not rest cleanly on the blade, or it may be misadjusted. It could also be that the wood wedge is simply too long and shavings get caught under it and clog the plane. With a used plane, it is rather rare that the shaving passage is too narrow, but this could also be a reason. In any case, it is important to check these possible reasons individually and to eliminate them if necessary..

Disassembling the plane

First, you need to disassemble the plane. To do this, remove the blade and remove the chip breaker (also called the lever cap). Grip the plane tightly around the hand guard, plane iron and wood wedge and then hit the rear end hard with a hammer. Many planes have an extra impact button here to protect the planer box from damage. If the iron does not come off, it may be that the iron has rusted and literally baked onto its wooden bed. If this is the case, it can be loosened by light strikes, alternately sideways left and right. Occasionally it also helps to strike the iron as if you wanted to set a thicker shaving.

With strong strikes, the wedge is loosened, and the plane iron is removed.

If it is a plane with chip breaker (jack plane), it must be unscrewed from the iron. A special chip breaker screwdriver is practical, where the blade has the right thickness and width for the very large screw head. With a normal screwdriver of the right size, it is easy to slip off because of the long shaft. To use such a screwdriver to unscrew the flap, either place the iron in the drawer of the planer bench or clamp it in the front clamp. This way, you can safely loosen the screw with both hands on the screwdriver and with the necessary force. If there are now chips under the flap, it must be reworked in any case.

Restoring the blade

First, you should check the plane side of the blade for flatness and rework it if necessary. A flat mirror side is not only a prerequisite for fast and effective resharpening of the blade, but also enables a precisely fitting support for the chip breaker. A diamond sharpening plate is best suited for dressing. With a few movements on the plate, you can quickly see if and where there are any irregularities. You can then also use the diamond plate to grind the mirror side flat. Depending on the condition of the mirror side, this can take some time. As if the blade is made of a good steel, it is worth this effort!

A flat mirror side is a prerequisite for sharpness and a tightly closing flap

Next, sharpen the blade using your preferred method.

Checking and straightening the chipbreaker

To subsequently check the support of the chip breaker, place the lever cap on the mirror side in the position in which it will later be installed. Hold the blade-lever cap package against the light so that you can see into the gap between the lever cap and the blade. If a light gap can be seen between the blade and the chip breaker edge, the lever cap is not lying flat and will need to be reworked. If the chip breakers do not fit properly, chips will be pushed between the blade and the lever cap during planing. It also can happen that the leading edge of the lever cap is deformed. In this case, the lever cap must also be reworked.

Even if the mounting screw exerts pressure on the lever cap, it must rest tightly on the front edge on the mirror side. The contact surface of the lever cap must therefore be slightly relief-ground. To do this, move the lever clap over a grindstone or, better, a trueing block with diamond coating so that the rear end of the lever cap is slightly lower than the cutting edge. Grind until the front edge of the lever cap is even again.

The chip breaker front edge is relief ground.

To break the leading edge, the chip breaker is tilted slightly.

The "cutting edge" of the chip breaker is ground at an angle of approximately 30-40°. Often this bevel surface is not straight but goes round into the surface. Some polish this surface so that the shavings can slide over it easily. The leading edge of the lever cap should not be sharp. Instead, a very fine bevel of about 80° is ground on it. To do this, place the lever cap vertically on your whetstone and tilt it very slightly towards the bevel. Now pull the chip breaker over the stone four or five times. This surface should only be very narrow so that it breaks the chip cleanly, but it does not stick to this surface.

Once the blade is sharp again and the lever cap is prepared, you can screw the two back together. The chip breaker edge should be as close as possible to the blade, one and a half to two times the chip thickness is ideal. In any case, no further than 0.5 mm from the blade.

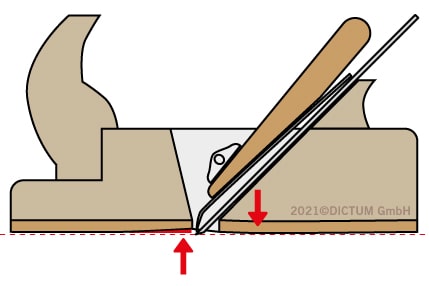

Checking and truing the plane sole

Now you can put the blade back into the planer. To fit the blade, hold the planer box so that the surface on which the blade rests is level. This way you can comfortably put the blade and wedge into the plane without the blade slipping through the plane mouth, and without risk of cutting yourself. To check and further work the plane sole, the blade should be positioned so that the cutting edge recedes about 0.5 to 1 mm behind the plane sole. Tighten the blade by hitting the wedge a few times. Now you can use a ruler to check the flatness of the sole in the longitudinal and transverse directions.

Graphic representation of typical wear marks on plane soles of older planes.

The reason for unevenness is often caused by a deformed planer box, due to moisture. More often, wear and fatigue of the wood is also responsible. To hold the blade in place, the wedge presses against the planer body towards the sole. This very often causes a slight bulge on the sole, in the area behind the cutting edge. At the same time, there is a slight indentation in the sole of the plane, usually directly in front of the cutting edge. This indentation is caused by wear, for example when breaking edges. With a smoothing plane, for example, it is very important to be able to remove thin shavings. To do this, the front edge of the plane's mouth must not under any circumstances spring back behind the plane's sole. You should therefore regularly check the plane sole and true it if necessary.

When dressing, the blade must be mounted and clamped. The cutting edge must spring back behind the plane sole. Hatch the plane sole with pencil lines so that you can easily see which areas of the sole are dressed. The area directly in front of the cutting edge is especially important. This is where the hatching should be most visible. Glue or clamp sandpaper, 80 to 120 grit, to a flat surface. A stone or glass plate or the machine table of a surface planer are suitable. You can now plane the sole on this with "planing" movements. Sand until all traces of pencil have been removed and there is once again a clean edge on the plane mouth. You can then break the long edges of the sole slightly. The leading and trailing edges of the sole should remain sharp, however, so that no shavings get under the plane sole during planing.

A flat surface is required for dressing, e.g. a machine table or granite slab.

Finally, it is advisable to wax the sole with planing wax or candle wax (paraffin) and polish it with a few shavings. Now the plane is fit again to be able to remove the finest shavings with it.

Summary

Wooden planes can deform, and the plane sole wears out over time. Therefore, in addition to re-sharpening, the plane sole must be regularly checked and, if necessary, trued. It is important that blade and wedge are mounted and that the plane is under tension. This applies not only to smoothing planes, but to all planes made of wood. This also applies to shoulder planes, moulding planes, dovetail planes, jointer plane, etc.

If the planer clogs, check that the lever cap is fitted and adjusted correctly and that the chipbreaker rests cleanly on the mirror side of the blade. If everything is correct here, then it is also at the chance that the wooden wedge is too long and needs to be shortened.

By the way: On new wood planes, the plane sole is very well dressed, but this is usually done in a relaxed state. With the dressing method described here, you can also optimize a brand new wood plane to be able to plane even finer shavings with it.