It's truly frustrating when a plane blade slips out of the sharpening jig, or a chisel gets improperly sharpened due to being clamped at the wrong angle in the sharpening guide. Often such annoyances are related to the quality and workmanship of the sharpening guides. We will guide you through the key factors to consider when selecting a sharpening guide for chisels and plane blades.

There are two categories of sharpening guides

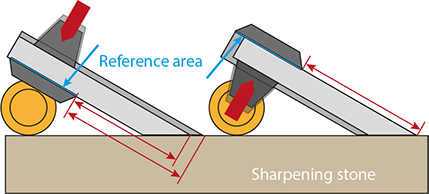

Sharpening guides for chisels and plane blades can be divided into two groups. With the sharpening guides of the first group, the tools are clamped onto a reference surface from the top. The extent to which the cutting edge of the tool protrudes from the guide depends on the blade thickness. An example of this clamping method is the Bridge City HG-4 Honing Guide.

Jigs can have two different clamping concepts

In the second group, the tools rest against the reference surface with their back. This has the advantage that the overhang of the cutting edge from the guide remains consistent, even with varying tool thicknesses. A typical representative of this group is the Stanley Honing Guide Set.

The simple Double Jaw Honing Guide features both clamping concepts. Chisels, whose blade thickness can vary significantly, are clamped with their back from underneath against the reference surface of the lower groove, whereas plane blades, typically ranging from 2.5 to 4 mm in thickness, rest on top of the reference surface of the upper clamping device.

What should you consider when opting for a sharpening guide?

- Can the tools be clamped in the sharpening guide?

Wide plane blades and chisels with straight edges pose no issues for the clamping mechanisms of most sharpening guides. However, the situation differs when dealing with narrow blades that provide only a small contact area when clamped from above and below, or with chisels that taper in thickness, such as Japanese chisels. To securely accommodate these, we recommend opting for a sharpening guide with lateral clamping for most blades. In cases where the sides of the chisel are heavily tapered (as seen in pod tools) or if the blades taper both laterally and in thickness (e.g. Japanese plane blades), they are best held by a guide featuring a broad pressure bar, such as in the Sharpening Guide with Horizontal Clamping. - Do the tools stay securely in the sharpening guide, or do they slip?

In order for the cutting edge or bevel to be sharpened at the desired angle, their position within the guide must remain fixed throughout the entire sharpening process. The tools should not shift laterally, forwards, or backwards within the sharpening guide. In some inexpensive sharpening guides, the holders are simply straight and so smooth that the tools do not grip securely and can easily slip or even pop out during sharpening. -

Can different sharpening angles be set with repeat accuracy?

High-quality sharpening guides are usually supplied together with a suitable setting gauge. Depending on the clamping concept of the sharpening guide (as mentioned above), these gauges either provide the common sharpening angles for chisels and plane blades (20°, 25°, 30°, or 35° cutting angles) or the amount of blade overhang required to achieve these angles when clamped into the guide. In this context, for example, the Veritas® Sharpening System II offers the option to create a micro bevel that is two degrees steeper with a simple turn of the brass roller.

Gauges for setting sharpening guides specify either the angle of the blade or its projection

- Workmanship and materials used

As with any tool, you should keep an eye on the workmanship and materials used in sharpening guides. Poorly manufactured cast parts and loosely fitting threads do not provide a secure grip. Rollers and bearings made of basic plastic wear out quickly and become loose. Don't be deceived by appearance alone. Colourful anodised aluminium and shiny surfaces look nice, but if the surfaces are too smooth or the clamping device only has a simple, straight shape, the tools will slip out easily.

Are there also affordable sharpening guides of good quality?

Quality always comes at a price. However, for those who possess only a few tools and sharpen them occasionally, the search for a budget-friendly sharpening guide becomes paramount. An example of good quality at an affordable price is the Double Jaw Honing Guide. Sharpening simple Western chisels becomes a hassle-free task with this guide. Chisels are securely fixed in the lower clamping groove. Yet, when firmly securing wide plane blades in the upper clamping device, the jaws might slightly elevate and push the blade upwards. To counteract this, a quick touch-up of the contact surfaces on the upper clamping device with a few strokes of a file can be performed. This process takes only a few minutes, and the Double Jaw Honing Guide will then firmly hold plane blades as well. Anyone who wishes to sharpen high-quality chisels and plane blades or even Japanese tools with partly conical blades will inevitably gravitate towards a high-quality sharpening guide.