- Which ones hold better, flat or wide wedges?

- In which direction should the wood fibres run in the wedge, crosswise or lengthwise?

- In which orientation should the slots run?

- Do wedged joints also hold without glue?

- How can I make detachable wood joints?

- Should wooden wedges be just sawn or also planed?

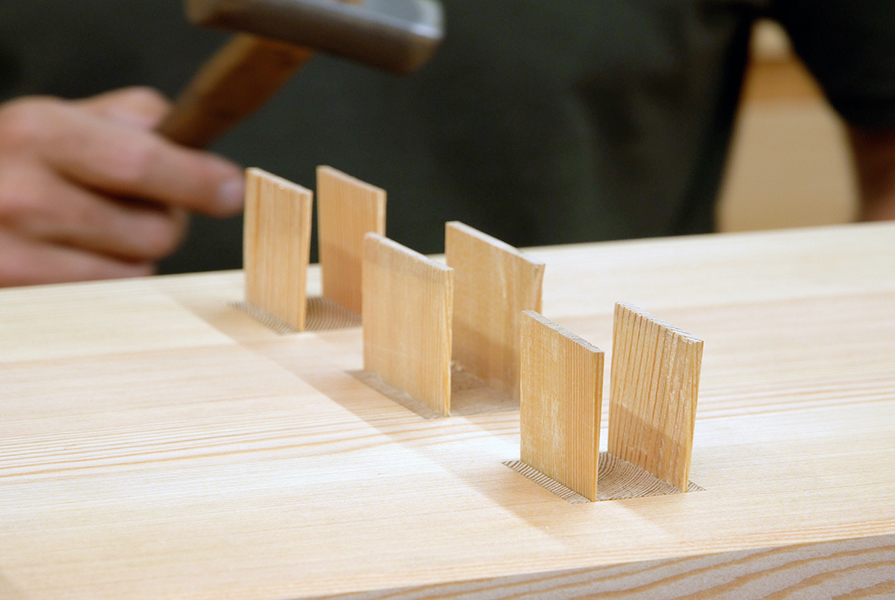

Wedged timber joints represent a versatile and reliable method for joining timber. There are numerous types of wedged joints, most commonly being mortise and tenon joints. With a bit of practice, you can craft enduring and sturdy wedged joints. Here are some valuable insights to assist you.

Which ones hold better, flat or wide wedges?

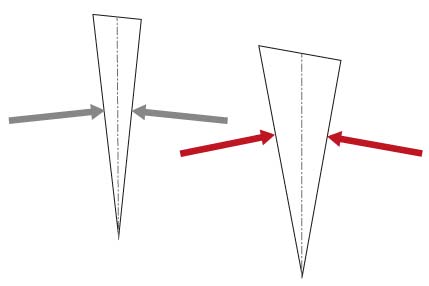

Flat wooden wedges generally exhibit higher self-locking and a better clamping effect compared to steep wedges, but they are less stable. Wedges with a greater pitch or with a steep angle have a less self-locking effect but are more resilient. You can take advantage of both aspects. For wood joints intended to be durable and glued, it is best to use flat, pointed wedges. If the joint allows, opt for two flat wedges instead of a single wide one. However, for a detachable wood joint (e.g. a classic wedged tenon), a slightly wider wedge is a better choice, as it provides greater stability and can be driven and removed better in the long run compared to a flat wedge.

With flat wedges, the lateral compressive forces act almost at right angles

In which direction should the wood fibres run in the wedge, crosswise or lengthwise?

For durable joints with wedges, the wood fibres should always run lengthwise through the wedge. Short fibres running across the wooden wedge will break easily, possibly before the wedge is driven far enough into the joint.

If the wood fibres run across the wedge, they are prone to break

In which orientation should the slots run?

Caution: wedges can split the workpiece! Therefore, make sure that the slots into which the wedges are driven always run across the wood fibres of the part in which the tenons are located. The long fibres will support the wedged joint. If the slots are parallel to the wood grain, the wedges can push the workpiece apart lengthwise and split it open.

Always place wedges across the wood grain so that they do not split the workpiece

Do wedged joints also hold without glue?

Yes, and quite effectively. Depending on the application and design, a wedged joint does not need to be glued. This allows for joints that accommodate wood movement (swelling and shrinking) and thus prevent cracks. If the wood joints are precisely crafted, it is often sufficient to apply some glue only to the wedges to ensure long-term durability of the joint.

How can I make detachable wood joints?

Wedges are an excellent way to create dismantleable joints! Many traditional pieces of furniture feature wedged wood joints. An example: Before modern joining systems were available, wardrobes often had their base, sides and top assembled with wedged joints, allowing for easy disassembly for transportation.

Another advantage of wedged joints is that the wedges can be re-tightened at any time, especially if the joint has loosened slightly due to weather effects. In addition, large wedges can keep the construction at a right angle.

The large wedge holds the side at a right angle

Should wooden wedges be just sawn or also planed?

For wedged joints to hold effectively, the wedges and slots must fit perfectly together. With simple wedged tenon joints, which are also glued, the accuracy of fit isn't as critical. However, the wedges should at least have the same width as the tenons. For wedged joints intended to be detachable and where the wedges hold the construction at an angle, the contact surfaces must be flat and aligned. The surfaces of the wedges should be smooth and planed. The joints need to be meticulously crafted and should not be undercut to allow the wedges' self-locking effect to work optimally. Even if the wedge joint is meant to be detachable, we recommend planing the rough surfaces left from cutting to ensure a clean fit.

To ensure optimal fit and ease of removal, the cut edges are planed