Making classic wood joints with machines is a very efficient way of working. If the machines are used correctly, you can hardly tell afterwards whether the wood joints were made by hand or with machines. We will introduce you to a method for making classic mortise and tenon joints on a circular saw.

This technique has been taught in our workshop »Classic Side Table« with Roland Heilmann. This project is an example of traditional furniture construction. Mortise and tenon give the aprons and table legs a stable join. The slots in the table legs are made with a router and finished with a chisel. First we will explain how to cut the tenons on the aprons.

For cutting the tenons, the aprons stand vertically on the machine table. This has the advantage that the length of the tenons can correspond to the maximum cutting height of the circular bench saw and the workpieces themselves can be of any length (their length is only limited by the room height above the circular saw).

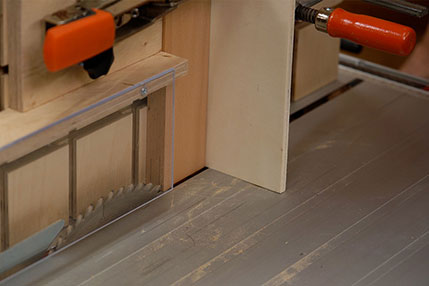

However, you cannot simply push the narrow, upright aprons over the circular bench saw by hand. That would be extremely dangerous. The aprons must be fixed with a special device, which has to ensure that you can repeat the cutting positions precisely and that the guidance is safe. We use the Multi T-track Clamping Device. There is a tutorial (german) on how to construct one of these.

The clamping device helps with tenon cutting.

Please note: Sawing the tenons is a special operation. The top guard on the riving knife must be removed for this. Alternatively, we have mounted a self-made cover on our Multi T-track Clamping Device. It covers the saw blade at the top and sides. After completing this special workstep, re-mount the top guard immediately!

The aprons are aligned using a vertical fence made of plywood. The plywood device is mounted with a batten and a Clamp for T-tracks and also serves as sacrificial fence to minimise tear-out. A Horizontal Clamp, mounted to the small board of the saw blade guard, presses the aprons firmly against the fence. Make sure that the aprons always lie correctly against the plywood fence and on the saw table. If you use a pull-push saw such as the (e.g. MAFELL Erika 85), the Multi T-track Clamping Device is fixed to the rip fence and the saw blade is pulled through the workpiece. With a normal circular bench saw, the Multi T-track Clamping Device can also be pushed past the saw blade along the rip fence.

The tenons are also cut on the table saw. Adjust the cutting height to the width of the tenon shoulder. An L-shaped auxiliary fence, which is clamped to the rip fence (e.g. with a Jorgensen One-Handed Clamp), ensures that the tenons are cut to the same length and at the same time protects against flying offcuts. The aprons are placed against the mitre gauge of the circular saw with their fronts butting up against the auxiliary fence. With a normal circular bench saw you then push the aprons over the saw blade, with a pull-push saw you pull the saw blade through the workpiece.

An auxiliary fence simplifies tenon cutting

Please note: Do not attempt to cut the tenons by setting the rip fence to the tenon length and placing the aprons against the mitre gauge. The sawed-off scraps will most likely get jammed between the saw blade and the rip fence and fly around unchecked!

The tenons can also be shortened using the method shown. When starting the cut, the aprons stand at right angles to the clamping surface of the Multi T-track Clamping Device and are placed upright against the mitre gauge when cut.

For simple mortise-and-tenon joints, e.g. with frame constructions, you can also cut the mortises using the Multi T-track Clamping Device. To do this, set the cutting height to the desired mortise depth and first saw both flanks of the mortise (on all workpieces). Then move the Multi T-track Clamping Device sideways step by step until the entire mortise is cut free. You can improve the result by slightly chiselling the bottom of the mortise to remove the marks of the circular saw blade.

Use the Multi T-track Clamping Device to also shorten tenons