There is a significant difference between working with solid wood and cutting chipboard or fibreboard. Long-fibre chips are produced especially during longitudinal cuts in solid wood. These chips need sufficient space on their way through the material in the space between the saw teeth, so-called gullet. Saw blades for longitudinal wood cuts, therefore, have fewer teeth than those for cross wood cuts. During the processing of sheet materials, short chips or fine dust are produced. This requires significantly less space in the gullet. The finer tooth arrangement improves the quality of the cut edges, which is advantageous, for example, when applying edging strips.

What tooth forms are there for circular saw blades?

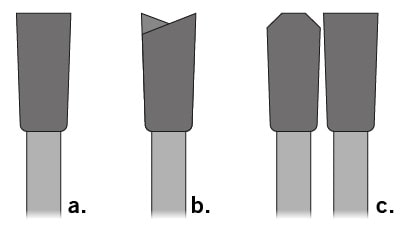

a. Flat tooth, for longitudinal cuts in solid wood

b. Alternate top bevel, for crosscuts in solid wood, veneered panels, as a universal tooth arrangement

c. Trapezoidal and flat tooth, for sheet materials with hard coating and plastics

What are the most important saw blades for handheld circular saws?

In addition to tooth form, the number of teeth also has a significant influence on the cut quality. As already mentioned, longitudinal cuts in solid wood produce much longer chips than crosscuts across the grain. So-called ripping blades, therefore, have significantly fewer saw teeth than universal blades for cross wood cuts or sheet materials, given the same diameter. So-called fine cut saw blades have the most saw teeth and, thus, provide a smooth cut surface.

What tooth forms are there for circular saw blades?

a. Ripping blade, with a flat tooth, 12 to 16 teeth, large gullets b. Universal blade for solid wood, with an alternate top bevel, 24 to 32 teeth

c. Universal saw blade for sheet materials, with an alternate top bevel or trapezoidal/flat tooth, up to 48 teeth

d. Fine cut saw blade, with trapezoidal and flat tooth or special tooth arrangement, up to 56 teeth

Depending on the machine and manufacturer, other saw blade types with different tooth arrangements are offered. Always consider the manufacturer's specifications of your machine and the descriptions of the saw blade provider when making your selection.