Hand-held sanding machines are available in a range of designs and sizes. The construction is almost identical on all of them, only the hand-held belt sander is different. In this post we will look at the various hand-held sanding machines and see which machine is best suited to which sanding jobs. We will only tackle sanding machines for wood and wooden surfaces, or power tools which are used in the wood workshop. For working on stone and metal there are other grinding machines which are rarely used in the wood workshop.

General construction

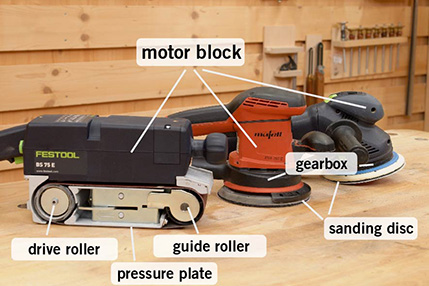

From simply looking at the abrasive on a hand-held sander it is obvious that it is an anomaly amongst hand-held sanders. Whilst all other sanders work with a flat abrasive (sharpening wheel, abrasive pads, etc.), the hand-held belt sander has a sanding belt mounted on two rollers, and a pressure plate. The drive roller, which is connected to the motor with a belt drive, moves the sanding belt. The guide roller helps to correct the position of the belt, ensuring it stays properly centred on the roller and pressure plate.

The hand-held belt sander differs considerably from other sanders

On most other sanders, a sanding disc or sanding pad sits under the motor and is coupled with the motor directly or via a gearbox. There is a different sanding motion depending on how this sanding disc or pad moves and as a result, a different sanding finish and stock removal.

Hand-held belt sanders

Hand-held belt sanders (e.g. Festool BS 75 E-Plus Belt Sander) work with sanding belts, which are moved in a single (linear) direction by the drive roller. Where the pressure plate is positioned, the sanding belt rests on the surface to be sanded. Compared to other hand-held sanders the abrasive is quickly moved over a large distance.

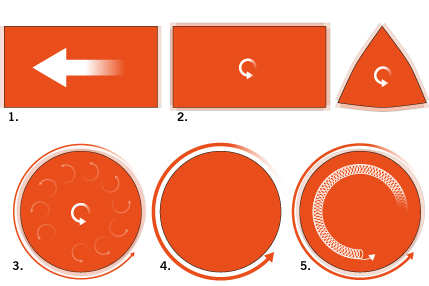

This drive design has a few benefits: Since the sanding belt is continuous, you could say that the sanding motion is «endless». The sanding motion is also linear, in a single direction (not rotary or oscillating). This is particularly practical for sanding solid wood, as wood surfaces should always be sanded in the direction of the grain to prevent scratches. In addition, the sanding dust is picked up straight from the abrasive and almost completely removed.

This makes hand-held belt sanders very effective with a high stock removal. They are perfect for working on large surfaces and for removing a lot of material, e.g. old paint. Many hand-held belt sanders are supplied with a mount, so that they can be used as compact stationary sanders for smaller workpieces. However, the stock removal is usually too aggressive and fast for fine sanding jobs, such as the final sanding of furniture surfaces, because surfaces can quickly become uneven and delicate edges are sanded off.

Rutscher and orbital sanders

The name »Rutscher« originates from the brand Festool ( Festool RTS 400 REQ-Plus) and generally speaking it's an orbital sander characterised by a rectangular sanding pad.

On orbital sanders (e.g. MAFELL UVA 115 E) the motor is situated over the sanding pad which is moved in circular oscillations by an eccentric drive. Compared to the belt sander, the sanding motion is quite short, which is why it is also called a »sanding stroke« or »oscillating circuit«. Depending on the machine and specification, common orbital sanders have a sanding stroke of 2 to 5 mm.

Overview of the sanding motion: 1. Belt sander, 2. Orbital sander/Delta sander, 3. Random orbit sander, 4. Angle grinder and 5. Rotex

The advantages of this drive design: The material removal is significantly less and is better controlled than with a belt sander. Due to their rectangular sanding pads, orbital sanders are also well suited to sanding close to the edges of rebates and in corners. Depending on the size of the oscillating circuit, orbital sanders are recommended for various sanding jobs. Orbital sanders with a stroke size of 5 mm are perfect for efficiently sanding larger solid wood and veneered surfaces (furniture carcasses, doors, etc.) for example, or for sanding off varnish with a high degree of control. In contrast, orbital sanders with an oscillating circuit of 2 mm are suited to polishing before finishing or for the intermediate sanding between coats of paint. When renovating or sanding down fixed pieces such as door or window frames, small, lightweight machines are particularly useful because they can be used for longer overhead or vertically with little effort.

Delta sanders

Most delta sanders (e.g. Festool DTS 400 REQ-Plus) are constructed like orbital sanders and have the same sanding motion. The only difference is the shape of the sanding pad. The triangular shape means they get into inner corners more easily e.g. in frames or drawers. There are only a few delta sanders available whose sanding pad moves sideways (oscillates), these are few and far between in woodworking.

Random orbit sanders

Most random orbit sanders (e.g. MAFELL EVA 150 E / 3) are also constructed in a similar way to an orbital sander, however, their round sanding disc pivots. The oscillating motion of the drive makes the sanding disc also rotate, or pivot, around its own axis.

The advantages of this drive design: This additional rotating motion ensures even material removal and produces a finer sanding result. The sanding motion is also bigger overall so sanding dust removal is better, which ensures low heat build-up. The oscillating circuit also differs in size on random orbit sanders, so there are machines for coarser or for finer sanding jobs. Small, lightweight devices (e.g. Festool ETS 125 REQ-Plus) are again ideal for renovation work.

Disadvantages: The round sanding disc is not suitable for sanding in corners. The rotation of the sanding disc is not controlled or is not controlled by a drive, which means it can be hampered by too much pressure or resinous surfaces.

Tip: Never apply pressure when sanding! The abrasive and the sander do the hard work for you. Pressure only hinders them and causes greater heat development, which when sanding paint in particular, is rather counter-productive

Angle grinders

The angle grinder deserves a mention too. This machine is suited to cutting materials as well as for grinding and polishing, and with the right sanding attachment (sanding disc or flap sanding disc) you can use it to work on wood as well. The angle grinder moves in circular sanding motions.

The advantages of this drive design: it removes material faster. With the right sanding attachments and abrasives, the angle grinder is suited to a wide variety of sanding jobs from very coarse (scraping) to very fine (polishing).

Disadvantages: The abrasive moves faster on the edge of the grinding wheel or sanding disc than in its centre. When sanding wood, clearly visible sanding marks rapidly appear. This can also lead to clumping/sticking in the middle of the sanding disc. So, even, controlled material removal is only possible if the speed of the angle grinder can be adjusted.

Otherwise the angle grinder is highly versatile. It can be used for cutting, carving, sanding and polishing wood, stone and metal, so no workshop should be without one.

Electric geared eccentric sanders

We learned earlier that hand-held sanding machines with an oscillating sanding motion create a fine, even sanding finish and that a rotating motion ensures fast material removal. On a geared eccentric sander (e.g. Festool RO 125 FEQ-Plus ROTEX) these two motions are combined. In contrast to normal random orbit sanders, the rotation of the sanding disc is not random, but controlled by a gear and can be switched on and off.

The advantages of this drive design: The combination of an oscillating and rotating action generates up to three times as much removal than on conventional random orbit sanders. As the rotating action (Festool use the term «rotary motion») can be switched on and off, the geared eccentric sander is highly versatile. It is equally well suited to coarse sanding (with rotary motion), fine sanding (without rotary motion) and for polishing varnished surfaces (with rotary motion).

The typical disadvantage of round sanding discs (not suited to inner corners) is offset on the Festool RO 90 DX FEQ-Plus ROTEX via the FastFix interface for changing sanding discs for a triangular-shaped disc. The ROTEX RO 90 can be converted into a delta sander in no time.