To work accurately, you need to clearly see what you are doing. In the commercial sector, the German »Technische Regeln für Arbeitsstätten - Beleuchtung und Sichtverbindung (ASR A3.4)« (technical guidelines for workplace safety in terms of lighting and line of sight) specify exactly which lighting conditions are required for different activities at the respective workplace. This includes above all the brightness and colour rendering of the lighting equipment. In the hobby sector, there are no standards that must be complied with for lighting. However, good light also helps here to better recognise details, so you can precisely mark, chisel, plane, or saw. We provide tips for the right lighting in your workshop.

How bright should a workshop be?

As already mentioned, the German ASR guidelines specify exactlywhat the light should be like at the workplace. For example, in woodworking, they recommend a lighting intensity of at least 200 lx (lux) at the saw gate, 300 lx for work at the workbench, and at least 500 lx for machine work. For surface finishing (sanding, varnishing) and veneer work, even a minimum of 750 lx is recommended.

Translated to the hobby area, this simply means: the finer and more precise a task, the brighter the workshop should be. A room with daylight and additional electric lighting is therefore ideal. If your hobby workshop is in the basement or garage, you should ensure adequate lighting conditions with ceiling lights and additional workplace lighting.

Another aspect is the age of the (hobby) craftsman. Visual acuity decreases with age. Especially for recognising details, older people need more light than younger people. This is not only the case when reading, but it also becomes apparent when working. So, don't be surprised if you find that you need glasses or simply more light for certain tasks that you used to do easily without any aid.

Avoid inconvenient shadows

Sufficient brightness also means that no unfavourable shadows are cast where you are working. The best work light is of little use if it is placed or hung in an unfavourable position, causing you to constantly cast shadows on your work. Therefore, pay attention to the correct placement of light sources.

Thanks to LED technology, light sources are now available in many different forms. In addition to traditional light bulbs, spotlights and fluorescent tubes, the technology now makes panel shaped lights possible, LED panels, which provide a more even illumination. LED panels with a low profile can also be installed in rooms with a low ceiling height (basement or garage).

The arrangement of the light source determines the shadow cast

Tip: For ceiling lighting with fluorescent or LED tubes, shadow casting can be minimised by arranging them crosswise or in a zigzag pattern.

What is better, warm or cold light in the workshop?

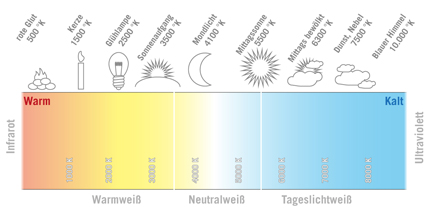

When it comes to the colour of light, there is a distinction between warm and cold light. This classification can initially be confusing, as it has nothing to do with actual temperature or weather. The light temperature is the colour that is selected on a spectrum from infrared through yellow and white to ultraviolet. It is measured in Kelvin, the base unit for temperature in the international SI system. Candlelight and traditional light bulbs, for example, have a temperature of approx. 1500 to 3000 K and emit warm light. Standard household fluorescent tubes emit a rather cool light of around 4000 K. »Standard light« ranges from 5000 to 6500 Kelvin and thus corresponds to the lighting conditions on a bright sunny day. With many LED lights, you can choose different colour temperatures between cold and warm.

In the range of 3500 to 5500 Kelvin, we speak of neutral white or daylight white

In the workshop, you should favour cold light around 4000 to 5500 K for two reasons. On the one hand, you can better judge the colour of woods and veneers or surface treatments and will not be unpleasantly surprised if, for example, you place a self-made and stained piece of furniture from the workshop in your sun-drenched living room. On the other hand, cold light is stimulating, while warm light has a calming effect. In the workshop, you want to work and stay focussed, and cold light supports this.

Targeted light for very precise work

When it comes to precision, a lot of light is required. Very bright light can be dazzling and then become tiring, and more energy is consumed. Accordingly, it makes sense to have targeted lighting in the areas that are used for precise work. Here are two examples from everyday workshop life:

1.Sharpening saws. When re-sharpening handsaws, the file must be placed at the correct angle between the saw teeth and moved back and forth. Furthermore, if it's a mitre or fine saw, the gaps between the small saw teeth are in the millimetre range. For such fine tasks, a lighted magnifier (e.g. LED Precision Optics) is very helpful. The optics magnify the details so that you can, for example, accurately assess the shape of the tooth tips. The ring-shaped LED light ensures bright and shadow-free illumination of the work area. A lighted magnifier also proves to be very useful for inlays or restoration work.

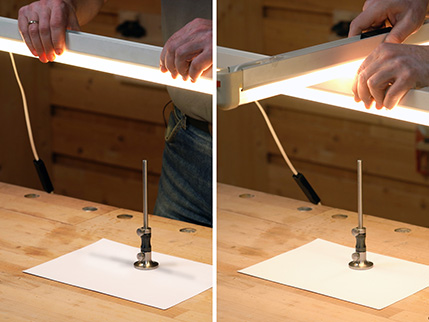

2. Turning thin-walled objects. To assess the wall thickness of lampshades or bowls and vessels with very thin walls during woodturning, many woodturners use a gooseneck lamp (e.g. Magnetic Base Light, Flexible Gooseneck). The flexible gooseneck allows you to align the light source so that the light shines through the workpiece walls. The brighter an area appears, the thinner the wall thickness (if you can see through, there's a hole in the workpiece). Unlike halogen lamps, LED lights have the advantage of producing hardly any heat. Fresh, wet wood remains moist for longer and does not warp due to the lamp. With the magnetic base, you can also easily attach the gooseneck lamp to other machines (e.g. scroll band saws, router tables, column drill presses etc.).

Shedding light in the dark

There are always situations where very little light is available for work, such as when connecting fixtures in kitchen or bathroom furniture, during maintenance of stationary machines, or inspecting cavities. The SPERAS V3 Mini Torch with Dual Light Source is an easy way to illuminate the dark. With 900 lumens, its performance is perfectly adequate for many tasks indoors and outdoors. This compact flashlight has four levels of brightness. With a magnet on the back, the SPERAS V3 can be attached to machine housings or a bonnet, for example. Additional features include UV light for checking banknotes and a fluorescent casing that makes it easier to find the lamp in the dark.

Brightness vs. light output

The brightness at the workplace is indicated in lux (lx), which measures the surface brightness on the work area. For many lights, especially torches, the light output is given in lumens (lm). This value does not indicate the brightness at the workplace but simply shows how much light the light source emits. The amount of light hitting an object decreases with distance from it. The further a light source is away from the work area, the lower the brightness at the workplace. Additionally, the optics of the lamp play a crucial role. If the light is spread widely over a large area, this can be helpful for assessing surfaces but reduces the brightness at greater distances.

If you need to move around while working and want to keep your hands free, a headlamp is a practical lighting solution. The SPERAS B47L-1 Headlamp offers several special features in this context. The B47L-1’s battery pack and LED spotlight are mounted on the side, reducing weight on the forehead and preventing glare in the face. The LED strip incorporated into the silicone strip at the front illuminates the surroundings. The LED spotlight and strip have two levels of brightness. An integrated hand sensor on the battery pack allows you to switch between functions without touching the lamp, which is extremely practical when your hands are dirty or when you’re wearing thick gloves!

Inspecting the inner workings of machines or instruments poses a particular challenge in terms of lighting. When illuminated with normal (torch) lamps, components in front often cast annoying shadows, tight spots remain dark, and small parts go unnoticed. With inspection lights, such as the Bend-A-Light, you can bring the light source directly into the smallest cavity. At the end of its flexible neck, there is a 5 mm LED bulb, allowing you to illuminate even hard-to-reach areas effectively. Instrument makers use these inspection lights, for example, to make it easier to detect and assess cracks in a soundboard.

But with all these practical lamps and lights, please don't forget the most important source of light and treat yourself to some sunlight from time to time after work!