Setting up and equipping their own workshop is the first challenge for many who start woodworking. After finding a suitable workplace and purchasing the usual hand tools, one question arises quite quickly: Which machines do I need?

- Considerations and prerequisites

- Basic equipment for a woodworking workshop for hobbyists

- Portable circular saw, circular bench saw and cross-cut saw

- Bandsaw or jigsaw?

- When do I need a router with a table?

- Which machines are needed for trueing and planing solid wood?

- Under which circumstances do larger stationary machines pay off?

- Drill stand or column drill press?

- Other power tools

Considerations and prerequisites

Prior to purchasing an adequate basic set of power tools and stationary machines, you should answer the following questions:

Which projects have you got planned? What would you like to build? This question is crucial for all further considerations. If you want to build furniture you will need different tools and machines than for woodturning or carving.

How much space do you have in your workshop? Before purchasing a large machine, always ask yourself whether there is enough space to set up and work with a stationary machine. In addition to the actual space required at the installation site, you also need sufficient space around the machine to feed and process material or workpieces. Machines that are rarely used also need space, which may then be lacking for other work.

What is your budget? Machines are always a slightly more expensive investment if you value quality. This is the case with hand-guided and stationary machines. Do not make the mistake of buying cheap »hobby machines«. In most cases, these devices are only designed for a very short service life and are accordingly equipped with inferior motors and bearings. If the budget is limited, second-hand machines may be an alternative.

HDo you have long-term goals or are your projects more short-term? If you need to be able to implement a project now and then use the machines rather infrequently, a machine hire company may be able to help you. If it is likely that you will use the machines on a regular basis in the long term, it is worth investing in high-quality machines.

Basic equipment for a woodworking workshop for hobbyists

If you want to hang a lamp or a shelf, there’s no alternative to a drill. If you use adequate bits, you will not necessarily need an impact drill. Most cordless screwdrivers have one gear for drilling and one for screwing. In addition, torque can be limited when screwing to prevent overtightening of the screws. These options are usually missing with inexpensive drills.

A jigsaw is also part of the machine equipment in many households where wood is worked with from time to time. It can be used to saw off skirting boards, cut prefinished parquet and laminate to size, and also to realise small projects (e.g. a bird house or garden table). Handle jigsaws are still widely used in the hobby sector. These are guided with a bow-shaped top handle far above the motor housing. In the professional sector, the flatter design with barrel grip has meanwhile become established. These jigsaws are more compact and are guided directly with the motor housing, which allows better control of the saw cut and cutting guidance from below (the jigsaw is pressed against the workpiece from below and the saw cut on the top is free of tears). The use of high-quality jigsaw blades that match the respective material (solid wood, parquet, laminate, plastic, etc.) has a significant influence on the quality of the saw cut.

Versatile jigsaw: Coping corners, internal cut-outs, curves and much more

Portable circular saw, circular bench saw and cross-cut saw

A plunge saw with guide rail can be used to cut almost anything that is otherwise cut on a circular bench saw. Another advantage of a plunge saw is its smaller footprint. Also, when working, it only requires the space necessary for the saw cut. With a stationary circular saw, additional space is needed for in- and outfeed in front of and behind the saw table.

A circular bench saw is always worthwhile when cutting more complex pieces of furniture with many parts in different dimensions. Setting the dimensions is much quicker with the circular bench saw than with a plunge saw. In addition, cutting small parts and narrow battens is not only faster and more accurate with a circular bench saw, but also safer.

Woodworking beginners often go for a cross-cut saw. But be careful, a cross-cut saw is designed for trimming cuts with limited cutting length. Its range of functions is very limited compared with a plunge saw or circular bench saw. A cross-cut saw is worthwhile if you have to trim a lot of battens, e.g. in interior finishing and when laying floors. It saves considerable time when cutting prefinished parquet or laminate and for the many mitre cuts on skirting boards.

Bandsaw or jigsaw?

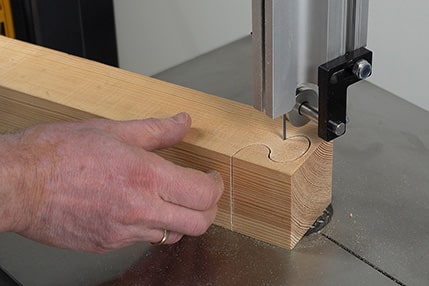

The jigsaw is ideal for cut-outs and mobile work, e.g. for kitchen assembly. In the long run, however, using it is exhausting (vibrations). The cutting height is also limited (maximum half saw blade length). A bandsaw enables finer saw cuts and greater material thicknesses. It runs much more quietly, ensures clean cut edges and the work is less strenuous in the long run. A bandsaw is also suitable for ripping thicker solid wood that is then to be levelled and planed to thickness. However, it cannot be used for interior cut-outs. Both machines, jigsaw and bandsaw, perform different tasks. A well-equipped woodworking shop should therefore have both.

A band saw can be used to cut smaller curves and thicker material than a jigsaw

When do I need a router with a table?

A router is a versatile power tool. You can do much more with it than just profile edges. With a few accessories and the right cutters, you can use it to make wood joints and even complete furniture construction projects. A table is not necessary for this. On the contrary, installing the router in the table or removing it is often cumbersome and discourages some craftsmen from using the router as a mobile tool. In addition, a router table takes up about as much space as a small circular table saw in the workshop. The purchase of a router table is worthwhile if the router is often used for complex wood joints or if you often work with templates. With a router table you have a better view of the work area and the cutter.

Different cutters for profiles and wood joints (profile/counter profile cutter)

You may opt for specialised routing jigs instead of a large router table. However, in many cases these are designed for a single type of wood joint (e.g. dovetails). A versatile alternative is the PantoRouter, with which you can make almost any classic wood joint. It requires little space, and it can be conveniently stored on a shelf or under the workbench.

Which machines are needed for trueing and planing solid wood?

If you want to work with solid wood, you will sooner or later reach a point where the range on offer in DIY stores no longer satisfies you, and you want to true and plane your material by yourself. Purists do it completely by hand. If this is too time-consuming, the first step can be to true rough boards and planks with a surface planer (e.g. Shinko AH200) and then plane them to the desired thickness by hand. If you also reach your limits here, you should think about a small mobile thickness planer (e.g. Shinko DH330). Both planers are designed for the hobby sector, deliver a good surface quality and require an acceptable amount of space. They are, however, only suitable to a limited extent for planing thick beams and long frame timbers.

Under which circumstances do larger stationary machines pay off?

A professional has a specialised machine for lots of tasks. This saves time when setting up and adjusting the tools, delivers optimised results and ensures safety. This makes the investment in such high-priced machines worthwhile for a professional craftsman. For a hobby woodworker, the »return of investment« is merely secondary. Working on professional machines that can be precisely adjusted and deliver top quality is simply more fun. The purchase of a larger stationary machine is always worthwhile if you have exhausted the possibilities of a power tool for the same tasks or if you want to increase your productivity.

Before purchasing a larger stationary machine, bear in mind that it often requires three-phase current and considerably more space than most »hobby machines«. The accessories are also usually somewhat larger (e.g. extraction system instead of workshop vacuum cleaner) and maintenance is more expensive (e.g. sharpening service for saw blades, plane blades, etc.).

Drill stand or column drill press?

An incorrectly drilled dowel hole, a screw that has been screwed in at an angle or a blind hole that has been drilled through by mistake, are not only annoying, they can also ruin a project shortly before completion. A pillar drill with a height-adjustable and inclinable support table, easy-to-operate drilling depth limitation and precise fence should therefore be part of every woodworking shop. A drill stand, in which a drill or cordless screwdriver is clamped, can only replace a pillar drill to a limited extent. They usually lack precision and exact alignment on the workpiece is awkward. However, drill stands are very helpful in mobile use, for example when it is necessary to drill a hole at the correct angle in a larger area or in a wall.

Other power tools

As part of a basic equipment, joining systems such as biscuit joiners (Lamello), Domino and DuoDoweler make sense if you plan to use them sufficiently often. Many tasks can also be implemented with a router (e.g. routing in flat dowels) or a drill with drill guide (e.g. dowel joints).

Grinding machines, orbital sanders, random orbital sanders, or belt sanders can be found at most hobby woodworkers. For many woodworkers, a carefully sanded surface is part of the perfect finish. However, if you work mainly with solid wood and the worksteps are carried out with care, planed surfaces provide an equivalent, if not even higher quality result. Sanding by hand is also quick and has the advantage that edges are less easily rounded, and veneers are not sanded through so quickly.

A hole jig increases the accuracy of a simple drill

An electric planer used to be part of the basic equipment for interior finishing. It was used to plane doors and adjust skirting boards. With a portable circular saw with guide rail, shortening a door leaf is much faster, more accurate and involves less mess. You can work the thin material thicknesses of skirts quickly with a small block plane, which also makes adjustments to crooked walls and floors much more delicate and safer.