There is a variety of different devices that extract dust and chippings. They range from simple household vacuum cleaners to permanently installed extraction systems with a chip container. In this post we will look at which dust extraction devices are suitable for which jobs and which machines they work best with.

What type of dust is produced in the wood workshop?

During assembly work with a hand drill, mainly drilling dust is generated, and when working with a jigsaw and a portable circular saw, coarser wood dust. The bore dust from stone and concrete, which is created, for example, when drilling holes for dowels, is fine and heavy. In contrast, when drilling and sawing composites, coarse wood dust is created because the sheet material is already made up of wood chips which are reduced to dust when cut.

In the bench room a mixture of dust is usually produced: Dirt from cleaning the floor and from grinding machines, and chippings from working with hand and power tools. This is predominantly wood dust, which is hazardous to health.

Some power tools, such as the router and electric planer, rapidly produce a huge amount of wood fibres and chippings which have a much greater volume than wood dust.

Four different types of dust are produced in the wood workshop

In the machine room mainly wood dust is produced at the stationary circular bench saw or sliding table saw and on the bandsaw, while on the planer (surface planer and thickness planer) a large amount of high-volume wood chips are produced in a very short time.

Is a household vacuum cleaner suitable for extraction?

A normal vacuum cleaner is not a suitable solution for the wood workshop. Firstly, the collection container is very small at between 3 and 6 litres. Secondly, the suction hose usually has a small diameter (approx. 26 mm) with only a comparatively low suction power. A normal household vacuum cleaner is only suitable for occasional work e.g. drilling holes in the wall or cleaning up after assembly work. The advantage of the vacuum cleaner is that generally speaking, it is really quiet.

What are workshop vacuum cleaners (wet and dry vacuum cleaners) used for?

Unlike the household vacuum cleaner, the collection container on most workshop vacuum cleaners sits below the suction unit, so that the dust vacuumed up goes straight into the container and isn’t drawn into a bag or container that sits in front of the motor housing. This means that the device can also be used on liquids with no danger to the electric motor. As a rule, workshop vacuum cleaners have a simple air filter without an additional dust bag. The collection container has a much greater capacity than a household vacuum cleaner. These workshop vacuum cleaners are mainly deployed in the non-woodworking environment or for cleaning tasks e.g. on a construction site or during assembly.

Simple portable dust collector with 50-litre container

What are the advantages of mobile dust extractors?

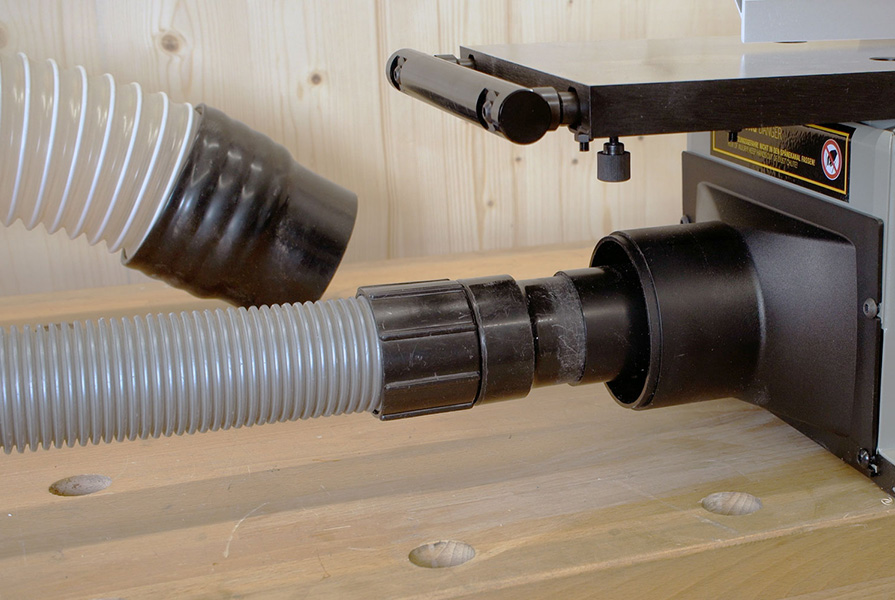

Mobile extractors are assigned dust protection classes (L, M and H), which are required by trade associations in the commercial sector. In the private sector, the dust protection classes play only a minor role. The important distinctions are mainly the volume of the collection container and the diameter of the suction hose. Most mobile dust extractors can be connected to larger suction hoses with a diameter of between 58 and 66 mm, as well as to flexible hoses with 27 to 35 mm diameter — the size of household vacuum cleaners as well as workshop vacuum cleaners. These hoses fit most power tools such as portable circular saws and routers. Hoses with a diameter of 58 to 66 mm are more than double the size and offer proportionally more room for coarse particles and bigger chips. Most semi-fixed machines like mobile circular table saws, router tables and small planing machines have corresponding suction connections.

The MAFELL S 200 high-capacity extractor expands the container volume of the MAFELL S 35 M Dust Extractor to 200 litres

The container volume of a mobile dust extractor is also important for the suction performance. A dust extraction device with a 4.5-litre container, can only vacuum up about one cut on a portable circular saw. When milling a rebate with a router, one of these dust bags is full after less than five minutes, the suction hose is clogged up and has to be unblocked again, a laborious job — and it all takes a lot of time. For all work that rapidly produces a large amount of bulky chips, such as milling with a router and planing with an electric plane or assembly plane, the mobile dust extractor’s container should have a capacity of at least 25 to 35 litres.

In addition, the airflow in a mobile dust extractor is filtered through a dust collection bag and one or more air filters at least twice, so is proportionally cleaner than with a simple workshop vacuum cleaner. A mobile dust extractor is always a sound investment in your health.

When does it make sense to use a mobile dust extractor?

When we previously talked about dust extraction devices, the mobile dust extractors were stationary devices in a manner of speaking. Most of them have casters so they can be moved about in the workshop, but they are not very easy to transport (e.g. to a construction site). However, their size has the advantage that the powerful ventilators and air filters needed can be installed and large dust containers and bags used. The diameter of the connections is correspondingly bigger (Ø 63 to 100 mm).

The top-mounted crank handle makes it easy to clean the air filter on this dust extractor

Extraction units are used in the workshop or machine room. They are recommended even if you’re working on semi-fixed machines (circular bench saws or router tables). For small planing machines (surface planers or thickness planers) a dust extraction device is much more convenient than a mobile dust extractor because it handles the large quantity of chippings much better. With stationary machines which are more powerful and produce a lot of chips very quickly, in the long term, using a dust extractor is inescapable. With the right size dust extractor you can plane, saw or mill for an hour at a time without having to change the chip bag in between.